Principle of Flash Distillation:

- Flash distillation involves a single-stage separation process where the liquid mixture is partially vaporized by rapidly reducing the pressure or increasing the temperature.

Methodology of Flash Distillation:

This is a sample ad placement!

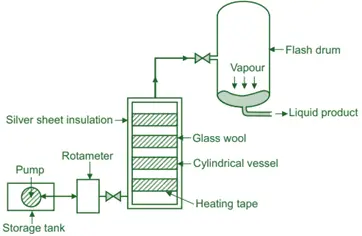

- Feed Introduction: The liquid mixture is introduced into a flash chamber.

- Pressure Reduction/Heating: The pressure is rapidly reduced, or the mixture is quickly heated, causing part of it to vaporize.

- Separation: The vapor and liquid phases are separated within the chamber.

- Collection: The vapor is condensed and collected, and the remaining liquid is withdrawn separately.

Uses:

- Used in the petroleum industry for crude oil refining.

- Separation of components with moderate differences in volatility.

- Chemical processing and waste treatment.

This is a sample ad placement!

Merits:

- Continuous process, suitable for large-scale operations.

- Efficient for mixtures with moderate differences in boiling points.

- Simple operation and lower energy consumption compared to multiple-stage processes.

Demerits:

- Less effective for mixtures with very close boiling points.

- Requires precise control of temperature and pressure.

- Limited to a single stage, providing less separation efficiency compared to multi-stage processes.

This is a sample ad placement!

Thank you for reading from Firsthope's notes, don't forget to check YouTube videos!