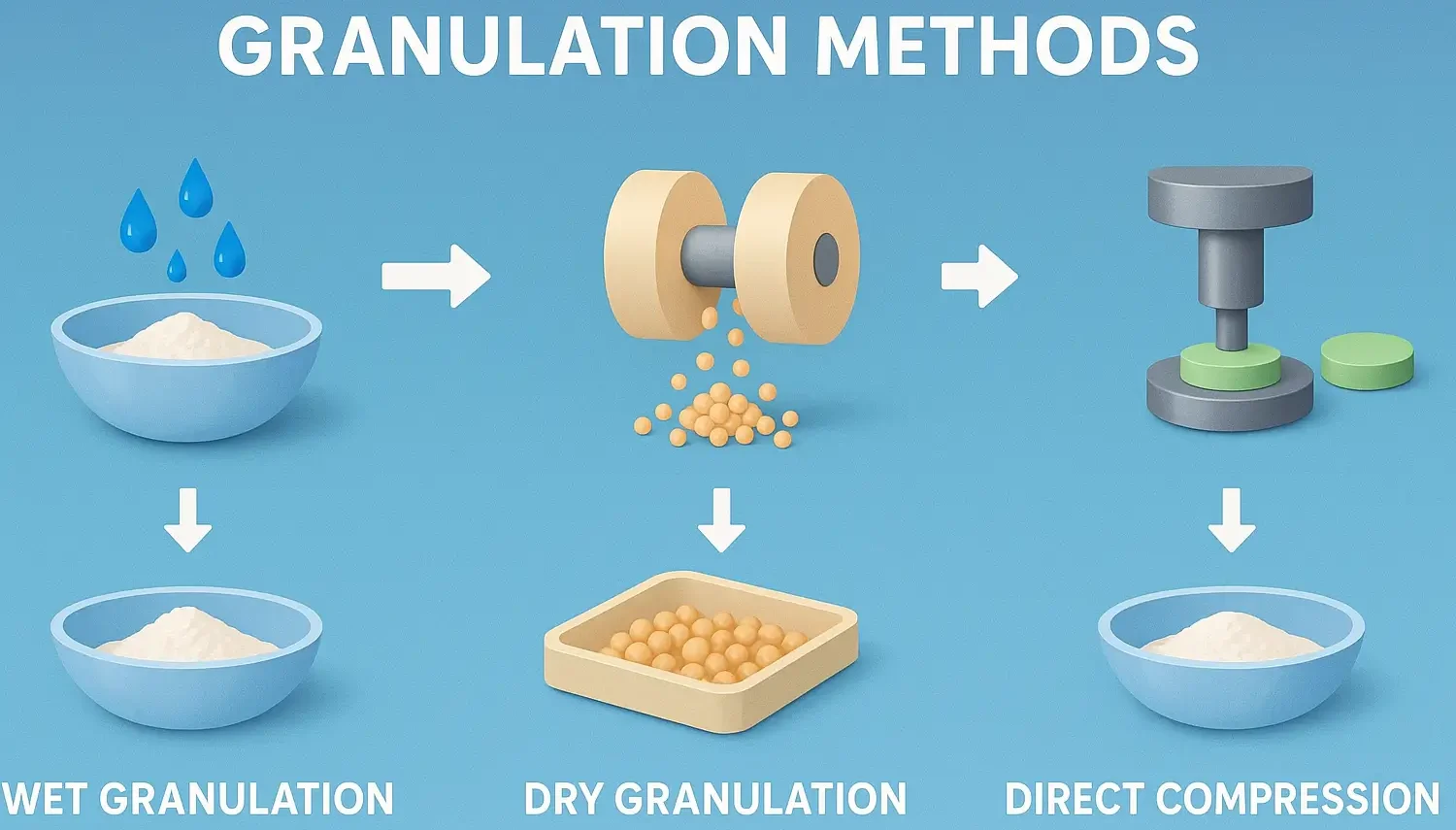

- Granulation Methods are the processes of particle size enlargement by forming agglomerates (granules) to improve flowability, compressibility, and uniformity of powders before tablet compression.

- It is classified into wet granulation, dry granulation, and direct compression.

1. Wet Granulation Methods:

Definition:

- Involves the use of a liquid binder to form granules by agglomerating the powder particles.

- Suitable for drugs that are not sensitive to moisture or heat.

Process:

-

Weighing and Mixing:

- API and excipients are blended uniformly.

-

Binder Addition:

- A liquid binder (e.g., starch paste) is added to form a wet mass.

-

Wet Sieving:

- Wet mass is passed through a sieve to form granules.

-

Drying:

- Granules are dried using an oven or fluid bed dryer.

-

Sieving (Sizing):

- Dried granules are resized to ensure uniformity.

-

Lubrication and Blending:

- Lubricants and glidants are added for compression.

Advertisements

Advantages:

-

- Improves flow and compressibility.

- Uniform drug distribution for low-dose drugs.

Disadvantages:

- Time-consuming and costly.

- Not suitable for moisture- or heat-sensitive drugs.

2. Dry Granulation Methods:

Definition:

- Granules are formed without using liquid binders.

- Suitable for moisture- or heat-sensitive drugs.

Process:

-

Weighing and Mixing:

- API and excipients are blended.

-

Slugging or Roller Compaction:

- Powders are compacted using high-pressure rollers (roller compactor) or slugging (tablet press) to form large sheets or slugs.

-

Milling and Sizing:

- Compact material is broken down into granules of desired size.

-

Lubrication and Blending:

- Lubricants are added before final compression.

Advantages:

-

- Suitable for moisture- and heat-sensitive drugs.

- Faster and cost-effective (no drying).

Advertisements

Disadvantages:

- High-pressure equipment needed.

- Poor binding properties and dust generation.

3. Direct Compression Methods:

Definition:

-

- Tablets are made by directly compressing powdered materials without prior granulation.

- Suitable for drugs with excellent flowability and compressibility.

Process:

-

Weighing and Mixing:

- API and excipients are blended.

-

Lubrication:

- Lubricants and glidants are added.

-

Compression:

- Direct compression into tablets using a tablet press.

Advertisements

Advantages:

- Simple, fast, and economical.

- Ideal for heat- and moisture-sensitive drugs.

Disadvantages:

- Requires excellent flowability and compressibility.

- Not suitable for low-dose drugs due to segregation.

- compressibility requirements.

- Lack of uniformity for low-dose drugs.

Comparison Table of Granulation Methods

| Aspect | Wet Granulation | Dry Granulation | Direct Compression |

| Process Complexity | Complex, multiple steps. | Moderate, fewer steps. | Simplest, no granulation. |

| Cost | High (equipment, time). | Moderate (no drying). | Low (minimal processing). |

| Suitability | Not for heat/moisture-sensitive drugs. | Suitable for sensitive drugs. | Ideal for free-flowing powders. |

| Tablet Strength | Strong and uniform. | Moderate strength. | Depends on powder properties. |