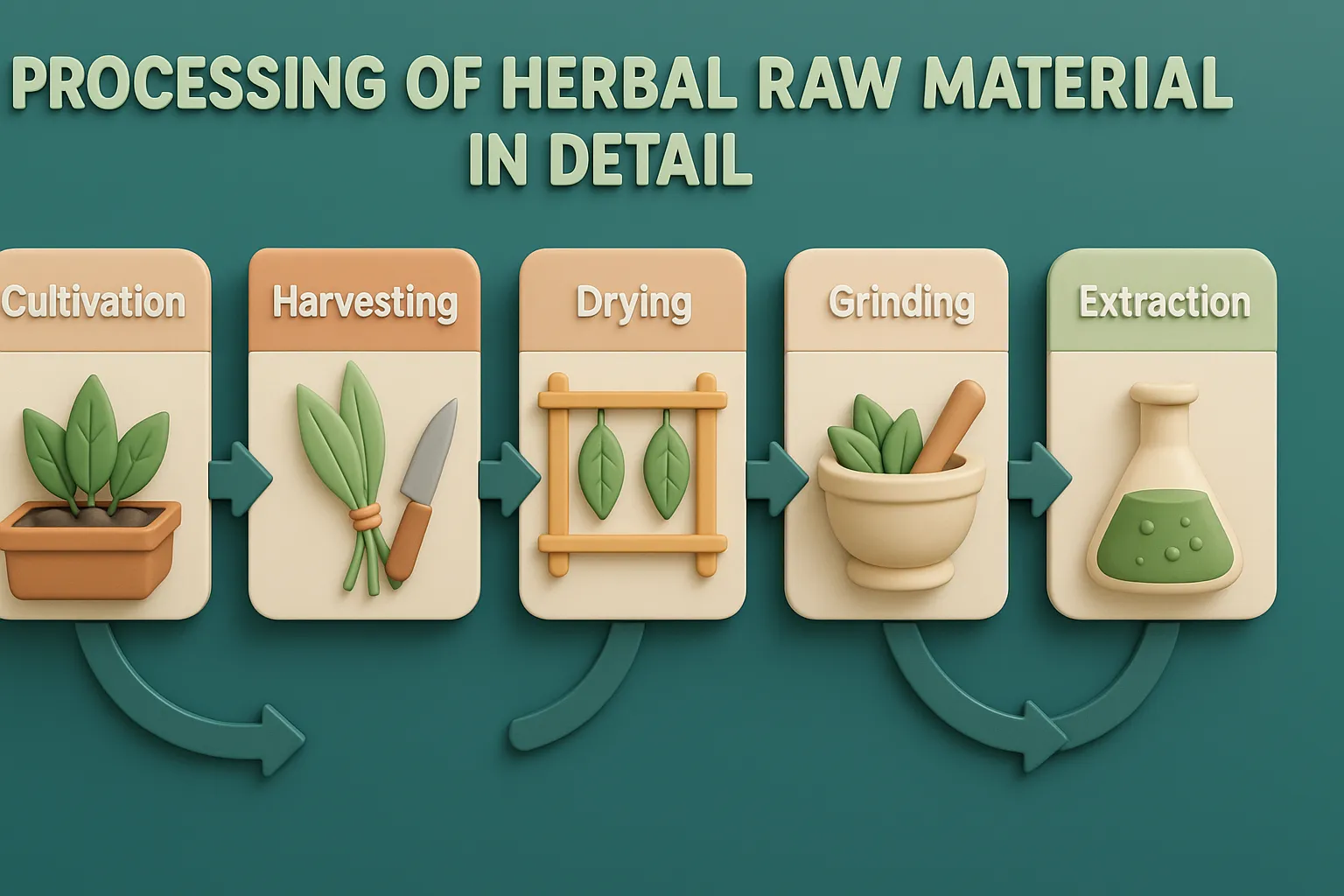

Processing of herbal raw material in detail covers drying, purification, size reduction, and storage to maintain quality and efficacy.

Processing of herbal raw material in detail

Once harvested, herbs undergo various processing steps to maintain quality, stability, and therapeutic potential.

-

Harvesting

- Timing is crucial—phytochemicals peak at specific growth stages (e.g., flowers in early bloom, roots in autumn).

- Methods: Manual or mechanical harvesting, with immediate handling to prevent spoilage.

-

Primary Processing

- Cleaning – Removes soil, insects, and damaged parts.

- Sorting & Grading – Separates materials by size and quality.

- Washing – Removes surface impurities (delicate herbs may skip this step).

-

Drying & Dehydration

- Sun Drying – Cost-effective but climate-dependent.

- Shade Drying – Protects delicate herbs from UV damage.

- Mechanical Drying – Controlled conditions ensure consistency.

- Freeze-Drying – Preserves volatile compounds but is costly.

-

Cutting, Grinding & Milling

- Increases surface area for storage and further processing.

- Fine grinding must be controlled to prevent oxidation and degradation.

-

Storage

- Herbs should be kept in cool, dry, and ventilated

- Airtight or vacuum-sealed packaging protects volatile or moisture-sensitive herbs.

-

Quality Control

- Regular testing for moisture, microbial load, pesticides, heavy metals, and active compounds ensures safety and potency.

-

Secondary Processing (Extraction & Formulation)

- Extraction (solvent, distillation, purification) is used to obtain active compounds.

- Formulation involves mixing with excipients and shaping into final products like capsules, tablets, or creams.

Click Here to Watch the Best Pharma Videos