- Laminar flow equipment is essential in maintaining a sterile and particle-free environment in aseptic areas.

How Laminar Flow Equipment Works

- Laminar flow equipment provides a uniform flow of filtered air in parallel layers, minimizing turbulence and preventing the spread of airborne contaminants.

- Here’s how it typically functions:

This is a sample ad placement!

-

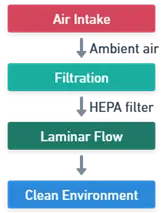

Air Intake:

- Ambient air is drawn into the unit through pre-filters that remove larger particles.

-

Filtration:

- Air passes through a HEPA (High-Efficiency Particulate Air) filter, which removes 99.97

Demo Ad

This is a sample ad placement! -

Laminar Flow:

- The filtered air is then directed in a smooth, laminar (unidirectional) flow towards the work area.

-

Clean Environment:

- The continuous flow of clean air prevents the ingress of contaminated air and protects the work surface or materials from airborne particulates.

Demo Ad

This is a sample ad placement!

Types of Laminar Flow Equipments

-

Vertical Laminar Flow Hoods:

- Airflow Direction: Air moves downward from the top of the cabinet.

- Applications: Commonly used for aseptic compounding and filling operations.

-

Horizontal Laminar Flow Hoods:

- Airflow Direction: Air moves horizontally from the back of the cabinet towards the operator.

- Applications: Used in laboratory settings for preparing sterile products.

Demo Ad

This is a sample ad placement!

Components of Laminar Flow Equipment

- HEPA Filters: Remove 99.97

- Pre-filters: Capture larger particles to extend the life of HEPA filters.

- Blowers/Fans: Provide consistent airflow across the work surface.

- Work Surface: Designed with materials that are easy to clean and disinfect.

Maintenance

- Regular Filter Changes: Periodic replacement of HEPA filters.

- Airflow Validation: Routine testing to ensure proper laminar flow.

- Cleanliness Monitoring: Regular cleaning and sterility checks.Top of Form

This is a sample ad placement!

Thank you for reading from Firsthope's notes, don't forget to check YouTube videos!