Purpose of Clean Area Classification

- Define Cleanliness Levels: Establish acceptable levels of particulate and microbial contamination.

- Regulatory Compliance: Meet standards set by regulatory bodies for sterile manufacturing.

Classification Standards

- ISO 14644-1: International standard for cleanrooms and associated controlled environments.

- EU GMP (European Union Good Manufacturing Practice): Provides guidelines for manufacturing medicinal products.

- FDA and USP Guidelines: US-specific regulations for sterile pharmaceutical production.

This is a sample ad placement!

ISO Cleanroom Classifications

- ISO Class 5 (Class 100): Maximum of 3,520 particles ≥0.5 μm per cubic meter.

- ISO Class 7 (Class 10,000): Maximum of 352,000 particles ≥0.5 μm per cubic meter.

- ISO Class 8 (Class 100,000): Maximum of 3,520,000 particles ≥0.5 μm per cubic meter.

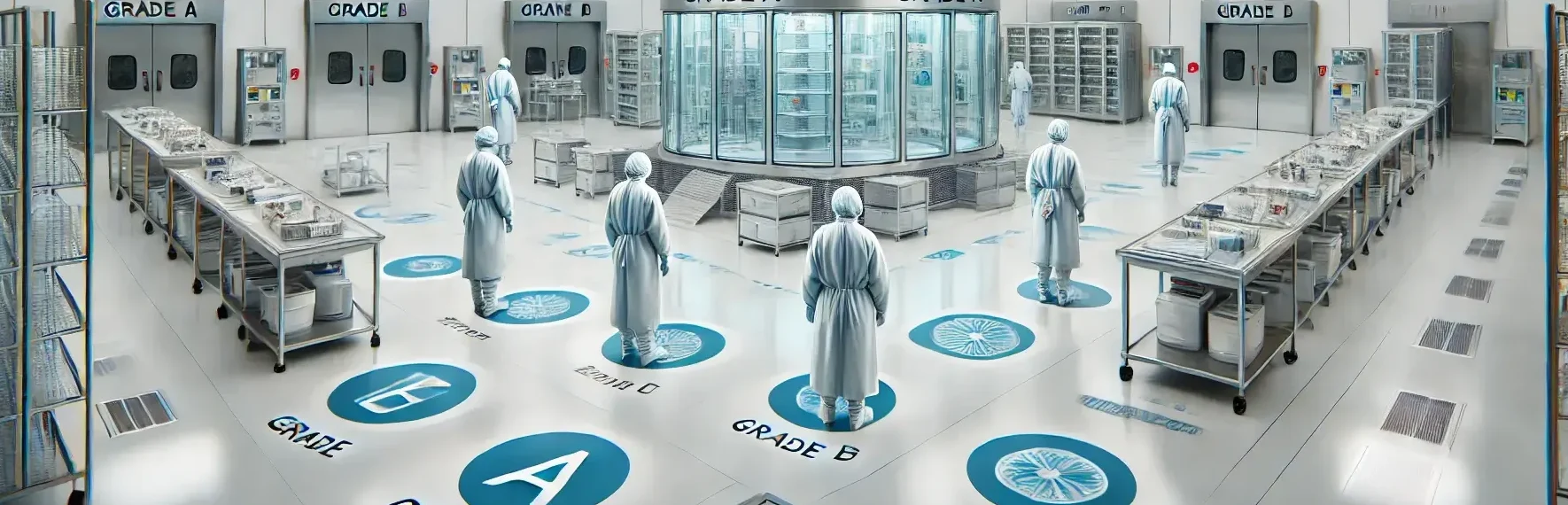

GMP Cleanroom Grades

-

Grade A:

- Highest level of cleanliness, for high-risk operations like filling and aseptic connections.

-

Grade B:

- Background environment for Grade A activities, such as the background for aseptic preparation and filling.

-

Grade C:

- Clean areas for less critical stages in sterile product manufacturing.

-

Grade D:

- Clean areas for less critical processes, such as handling of components after final cleaning.

This is a sample ad placement!

Microbial Limits of Clean Area Classification

- Non-Viable Particles: Limits set for airborne particles based on cleanroom classification.

- Viable Microbial Counts:

- Air Samples: Colony-forming units (CFUs) per cubic meter.

- Surface Samples: CFUs per plate or swab area.

Monitoring and Compliance

-

Environmental Monitoring Program:

- Regular Testing: Scheduled monitoring of air and surfaces.

- Trend Analysis: Evaluate data over time to detect deviations.

-

Certification and Recertification:

- Initial Qualification: Validate cleanroom performance upon setup.

- Periodic Requalification: Regular re-testing to ensure ongoing compliance.

This is a sample ad placement!

Cleanroom Design Considerations

- Airflow Patterns: Design to prevent turbulence and recirculation of particles.

- Room Pressurization: Positive pressure gradients from cleaner to less clean areas.

- Material and Personnel Entry: Use airlocks and gowning rooms to maintain pressure differentials.

Thank you for reading from Firsthope's notes, don't forget to check YouTube videos!