Principles of Twin Shell Blender:

- The twin shell blender operates on the principle of diffusive blending, utilizing the tumbling motion to mix materials.

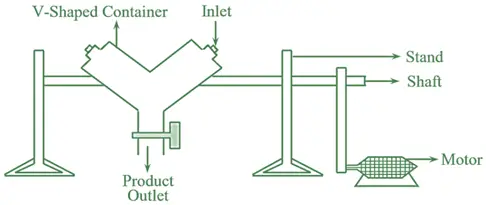

Construction of Twin Shell Blender:

- Vessel: Two cylindrical sections joined at an angle to form a V-shape.

- Drive System: Includes a motor and gearbox for rotation.

- Support Frame: Holds the vessel securely.

- Loading and Unloading Ports: For adding and removing materials.

- Optional Intensifier Bars: To enhance mixing of difficult-to-blend materials.

-

This is a sample ad placement!

Working:

- Materials are loaded into the V-shaped vessel.

- The vessel rotates, causing materials to tumble and cascade within the two arms of the V.

- The repetitive movement leads to thorough blending of the materials.

- After achieving the desired blend, the contents are discharged.

Uses:

- Pharmaceuticals: Blending powders and granules.

- Food Industry: Mixing dry ingredients.

- Chemical Industry: Blending fine chemicals and powdered materials.

This is a sample ad placement!

Merits:

- Efficient for free-flowing and dry materials.

- Simple and effective design.

- Gentle mixing action, preserving particle size and shape.

- Easy to clean and maintain.

Demerits:

- Inefficient for cohesive or sticky materials.

- Limited to batch processing.

- Not suitable for large-scale production due to volume constraints.

This is a sample ad placement!

Thank you for reading from Firsthope's notes, don't forget to check YouTube videos!