Principles of Ribbon Blender:

- The ribbon blender uses convective mixing by means of a helical ribbon agitator that moves materials both radially and laterally.

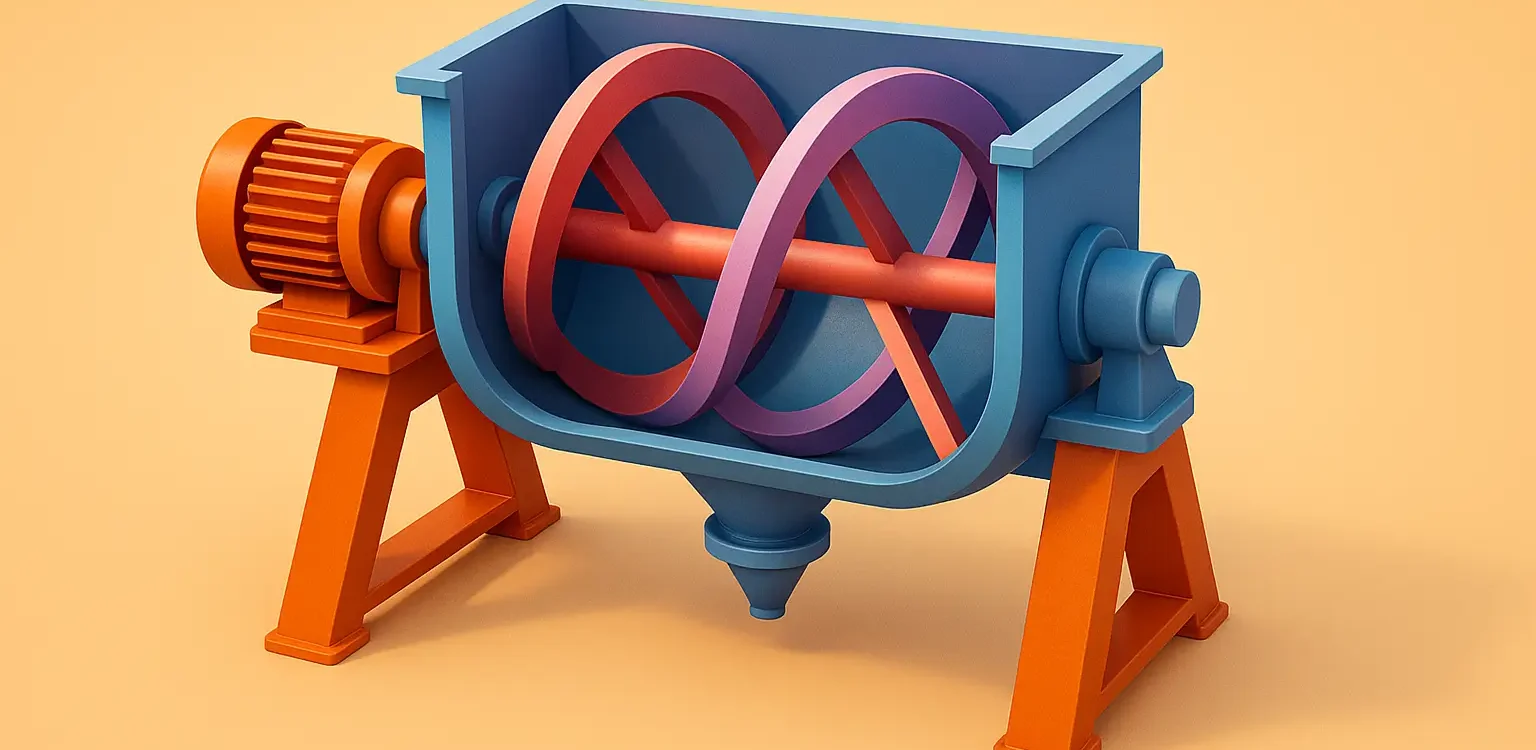

Construction of Ribbon Blender:

This is a sample ad placement!

- Trough: U-shaped horizontal trough that holds the materials.

- Ribbon Agitator: Double helical ribbons mounted on a central shaft.

- Drive System: Motor and gearbox to rotate the ribbon agitator.

- Support Frame: Sturdy frame to support the trough and drive system.

- Loading and Unloading Ports: For adding and discharging materials.

- Optional Features: Heating or cooling jackets, spray nozzles for adding liquids.

Working:

- Materials are loaded into the trough.

- The agitator rotates, with the inner ribbon moving materials towards the center and the outer ribbon moving materials towards the ends.

- This counter-flow action ensures thorough mixing.

- The process continues until the desired homogeneity is achieved.

- The mixed product is discharged through a bottom valve or port.

This is a sample ad placement!

Uses:

- Food Industry: Mixing dry powders, granular ingredients, and pastes.

- Pharmaceuticals: Blending powders, granules, and moist materials.

- Chemical Industry: Mixing fine chemicals, pigments, and other powders.

- Construction: Mixing dry mortar, plasters, and cement blends.

Merits:

- Versatile, can handle a variety of materials including dry powders, pastes, and slurries.

- Efficient mixing action ensures homogeneity.

- Can be equipped with heating/cooling jackets for temperature-sensitive processes.

- Suitable for continuous and batch operations.

This is a sample ad placement!

Demerits:

- Can be energy-intensive.

- Not suitable for highly cohesive or sticky materials.

- Cleaning can be challenging due to the complex structure of the ribbon agitator.

- May generate heat, which can be detrimental to heat-sensitive materials.

Thank you for reading from Firsthope's notes, don't forget to check YouTube videos!