Principles of Planetary Mixers:

- Planetary mixers operate on the principle of planetary motion, where one or more mixing blades rotate around their own axis while simultaneously orbiting around a central axis.

- This ensures thorough mixing of the materials.

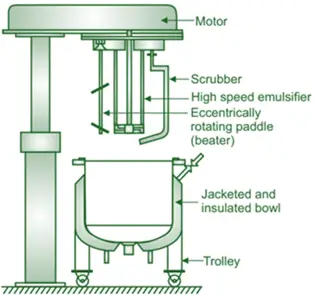

Construction of Planetary Mixers:

This is a sample ad placement!

- Mixing Bowl: A stationary bowl that holds the materials.

- Planetary Blades: One or more blades attached to a central hub that rotates around the bowl.

- Drive System: Includes a motor and gearbox to drive the planetary motion.

- Lifting Mechanism: Allows the bowl to be raised or lowered for loading and unloading.

- Optional Attachments: Various blade designs, scrapers, and heating/cooling jackets.

Working:

- Materials are loaded into the mixing bowl.

- The blades rotate around their own axis and simultaneously around the central axis, creating a planetary motion.

- This ensures thorough and uniform mixing of the materials.

- The mixed product is discharged by lowering the bowl and removing the contents.

This is a sample ad placement!

Uses:

- Pharmaceuticals: Mixing creams, ointments, and suspensions.

- Food Industry: Blending dough, cake batter, and pastes.

- Chemical Industry: Mixing adhesives, sealants, and other viscous materials.

Merits:

- Highly efficient mixing due to planetary motion.

- Suitable for a wide range of viscosities.

- Easy to change mixing attachments for different applications.

- Can be used for small to medium batch sizes.

This is a sample ad placement!

Demerits:

- Limited to batch processing.

- Higher initial cost due to complex design.

- Cleaning can be challenging, especially with sticky materials.

Thank you for reading from Firsthope's notes, don't forget to check YouTube videos!