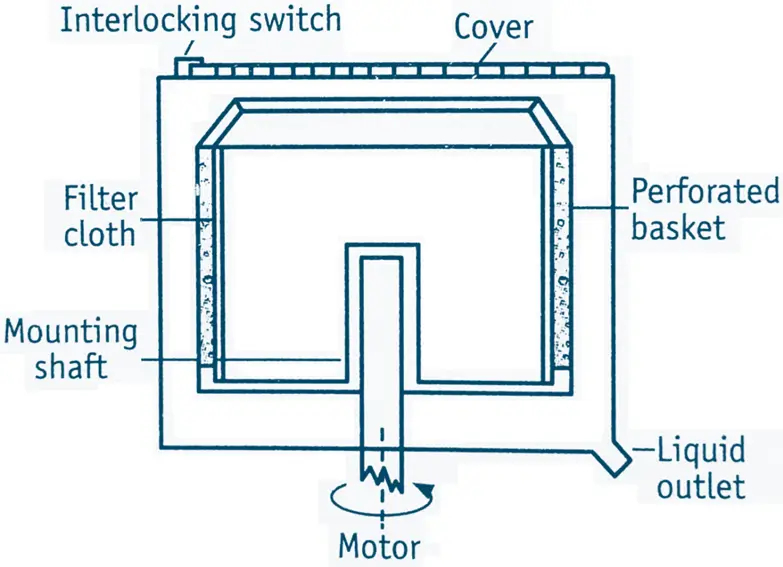

Principles of Perforated Basket Centrifuge

- The perforated basket centrifuge operates on the principle of centrifugal force, which separates solids from liquids in a slurry by spinning the mixture at high speeds.

- The centrifugal force drives the liquid through the perforations in the basket, leaving the solid particles behind.

Construction of Perforated Basket Centrifuge

- Basket: Cylindrical basket with perforated walls.

- Drive System: Motor and spindle that rotate the basket at high speeds.

- Housing: Outer casing that contains the basket and collects the separated liquid.

- Feed System: Mechanism to introduce the slurry into the basket.

- Discharge System: Mechanism to remove the separated solids from the basket.

- Control Panel: For controlling the operational parameters like speed and timing.

This is a sample ad placement!

Working

- Loading: The slurry is fed into the rotating basket.

- Centrifugation: As the basket spins, the centrifugal force drives the liquid through the perforations in the basket wall.

- Filtration: The solid particles are retained on the inner surface of the basket, forming a cake.

- Discharge: After the separation is complete, the machine is stopped, and the solid cake is discharged manually or through an automated system.

- Collection: The separated liquid is collected in the housing and drained off through an outlet.

This is a sample ad placement!

Uses

- Chemical and pharmaceutical industries for solid-liquid separation.

- Food and beverage industry for clarification and purification processes.

- Wastewater treatment for sludge dewatering.

- Mining and mineral processing for ore and mineral separation.

Merits

- Effective for separating fine particles.

- High filtration efficiency.

- Relatively simple and robust construction.

- Can handle large volumes of slurry.

This is a sample ad placement!

Demerits

- Requires manual intervention for cake removal.

- Limited to batch processing.

- Potential for clogging of perforations.

- Higher maintenance due to moving parts.

Thank you for reading from Firsthope's notes, don't forget to check YouTube videos!