Introduction to Aseptic Processing:

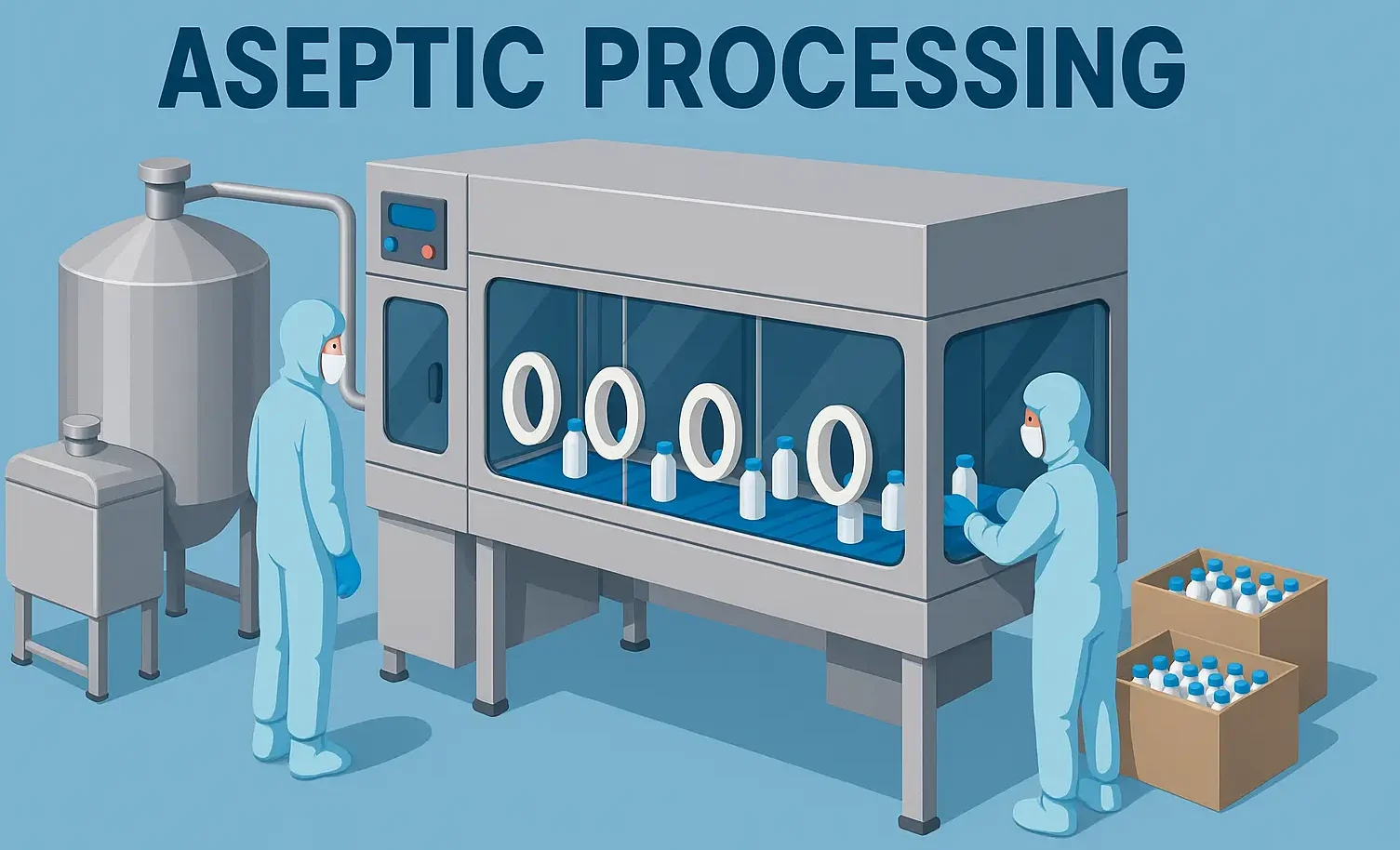

Aseptic Processing Production is the technique of manufacturing sterile products by ensuring the sterilization of the drug, container, and closure separately before combining them under sterile conditions.

Aseptic Processing Production prevents microbial contamination during the formulation of parenteral and other sterile dosage forms, ensuring product safety and efficacy.

-

Key components include:

- Sterile Environment: Production in cleanrooms with controlled air quality.

- Sterile Equipment and Materials: All components must be sterilized before use.

- Personnel Training: Operators must be trained in aseptic techniques to minimize contamination.

- Aseptic Techniques: Including proper gowning, minimizing air turbulence, and maintaining sterile barriers.

- Environmental Controls: Continuous monitoring of air quality, temperature, and humidity.

- Container and Closure Sterilization: Ensuring that containers (vials, ampoules) and closures are sterile before filling.

Critical Steps in Aseptic Processing:

- Preparation: Sterilization of components and materials.

- Filling: Using aseptic filling machines that maintain a sterile environment during the transfer.

- Sealing: Sealing containers without compromising sterility.

- Inspection: Ensuring no particulate contamination and verifying the integrity of seals.

Advertisements

Advantages:

- Maintains Integrity of Heat-Sensitive Drugs: Suitable for biologics and proteins.

- Flexibility in Formulation: Allows for complex formulations that might degrade under terminal sterilization.

Challenges:

- High Risk of Contamination: Requires stringent controls and validation.

- Complex Manufacturing Processes: Necessitates specialized equipment and trained personnel.