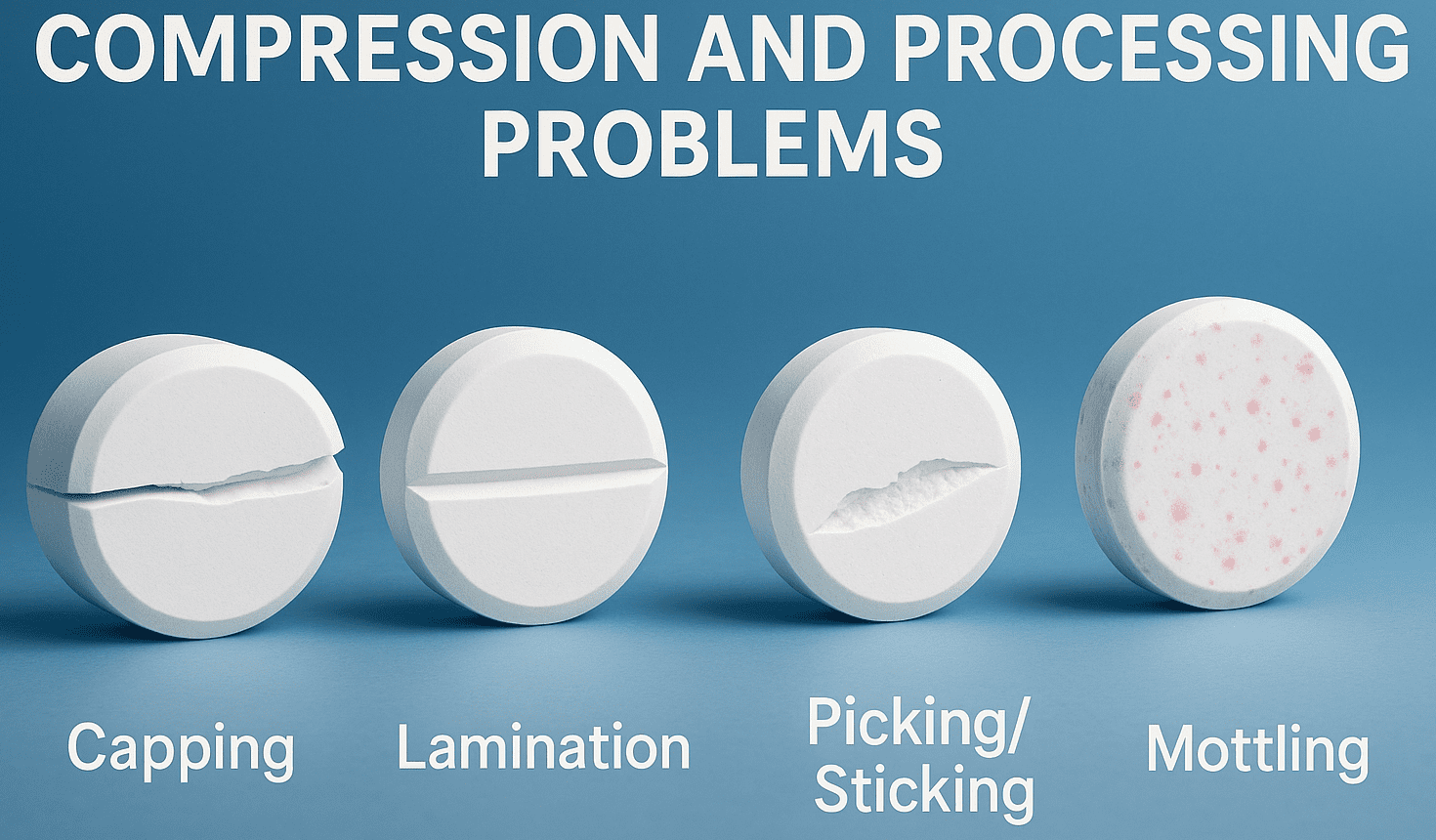

Compression and Processing Problems

Compression and processing problems is the final step in tablet manufacturing, where granules are pressed into solid tablets using a tablet press. Compression and Processing Problems• Definition: Issues encountered during tablet manufacturing affecting quality, uniformity, or efficiency.• Causes: Poor formulation, improper equipment settings, or environmental conditions.• Impact: Defects like capping, lamination, or sticking Several challenges … Read more