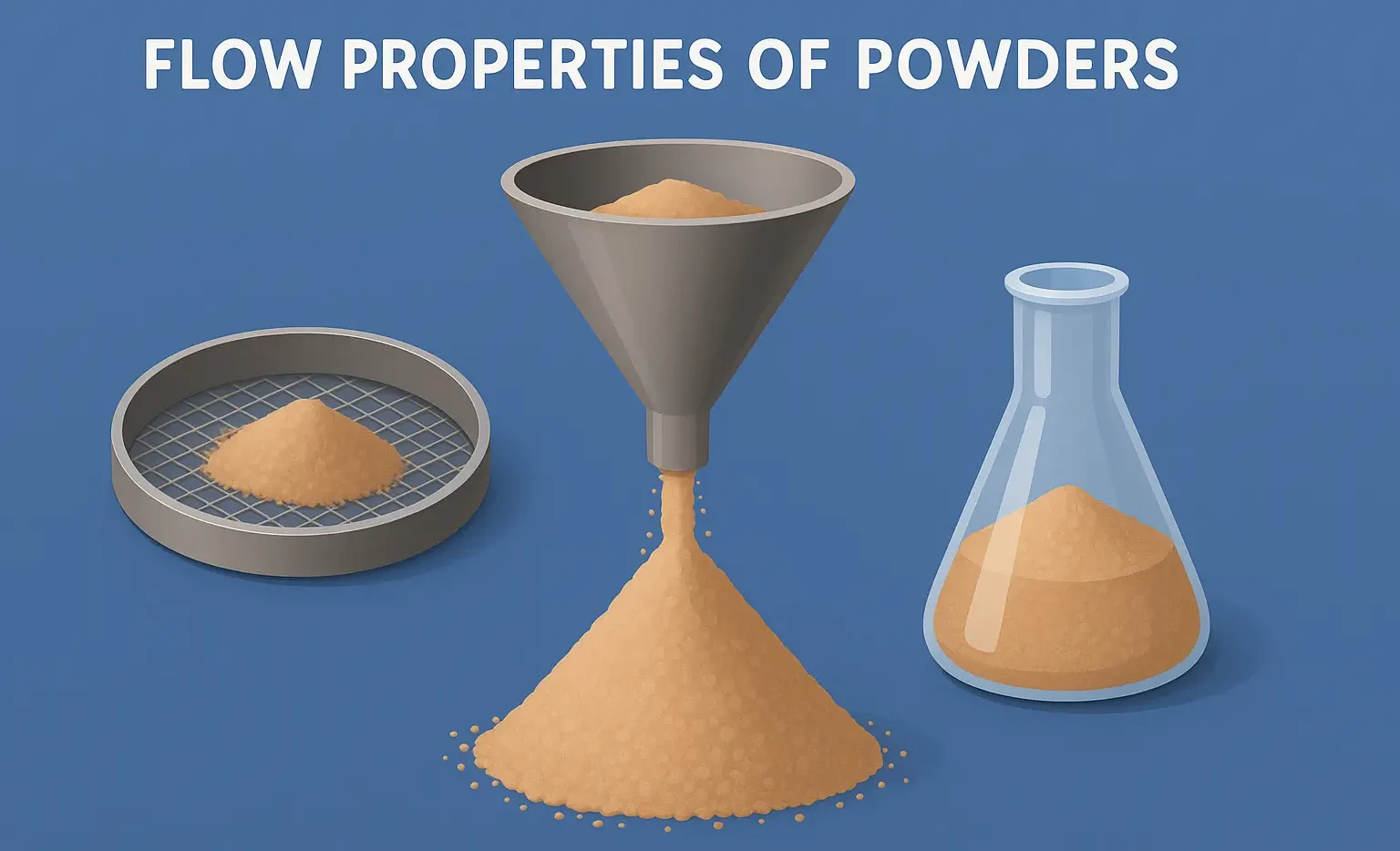

Flow Properties Of Powders

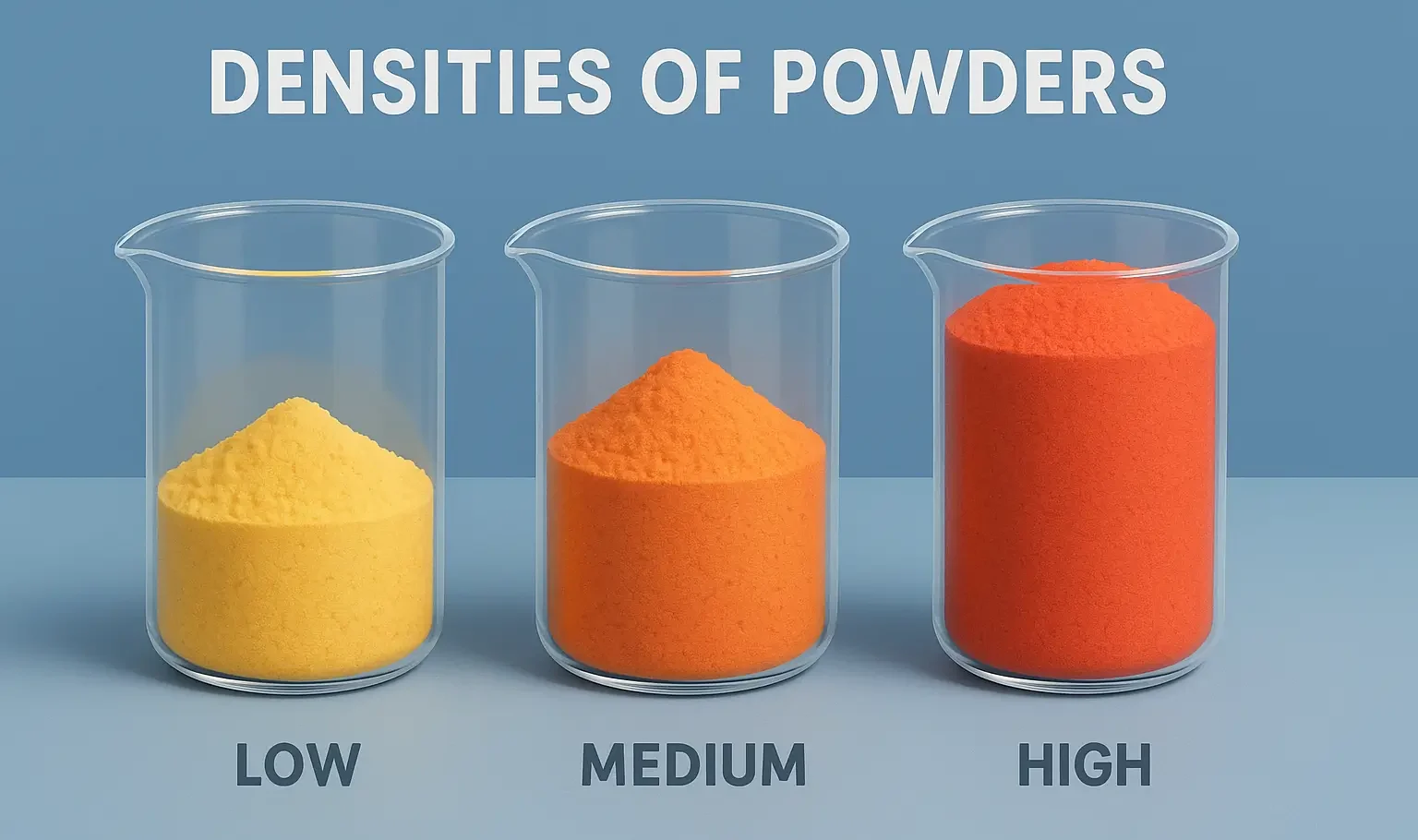

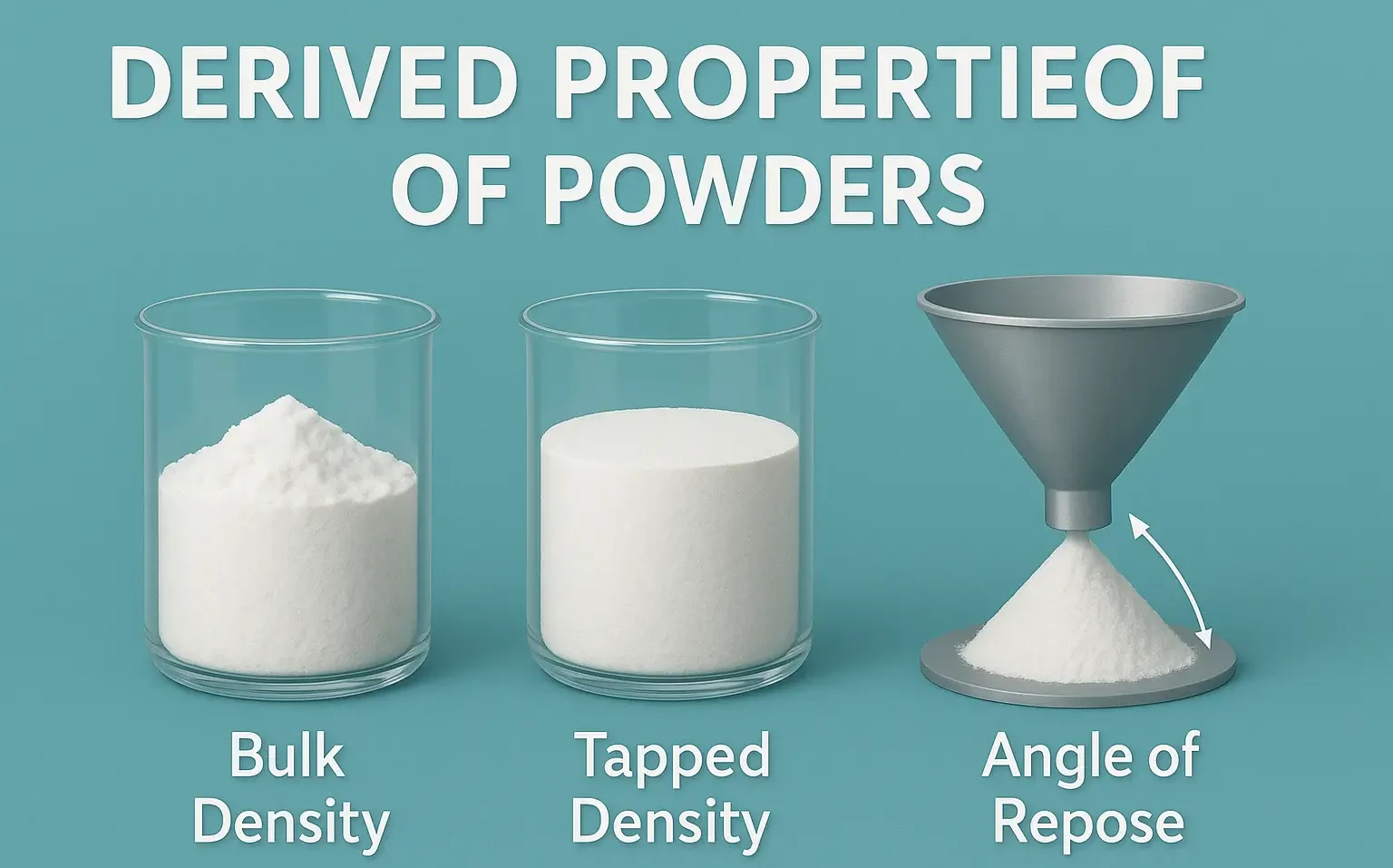

Flow Properties Of Powders describe how particles move, pack, and discharge in pharmaceutical processing. Flow Properties Of Powders affect mixing, granulation, tableting, and overall product quality. Powder flow is critical for operations like tablet compression, capsule filling, and granulation. Methods to Evaluate Flow: 1 Angle of Repose Angle formed when a powder is allowed to … Read more