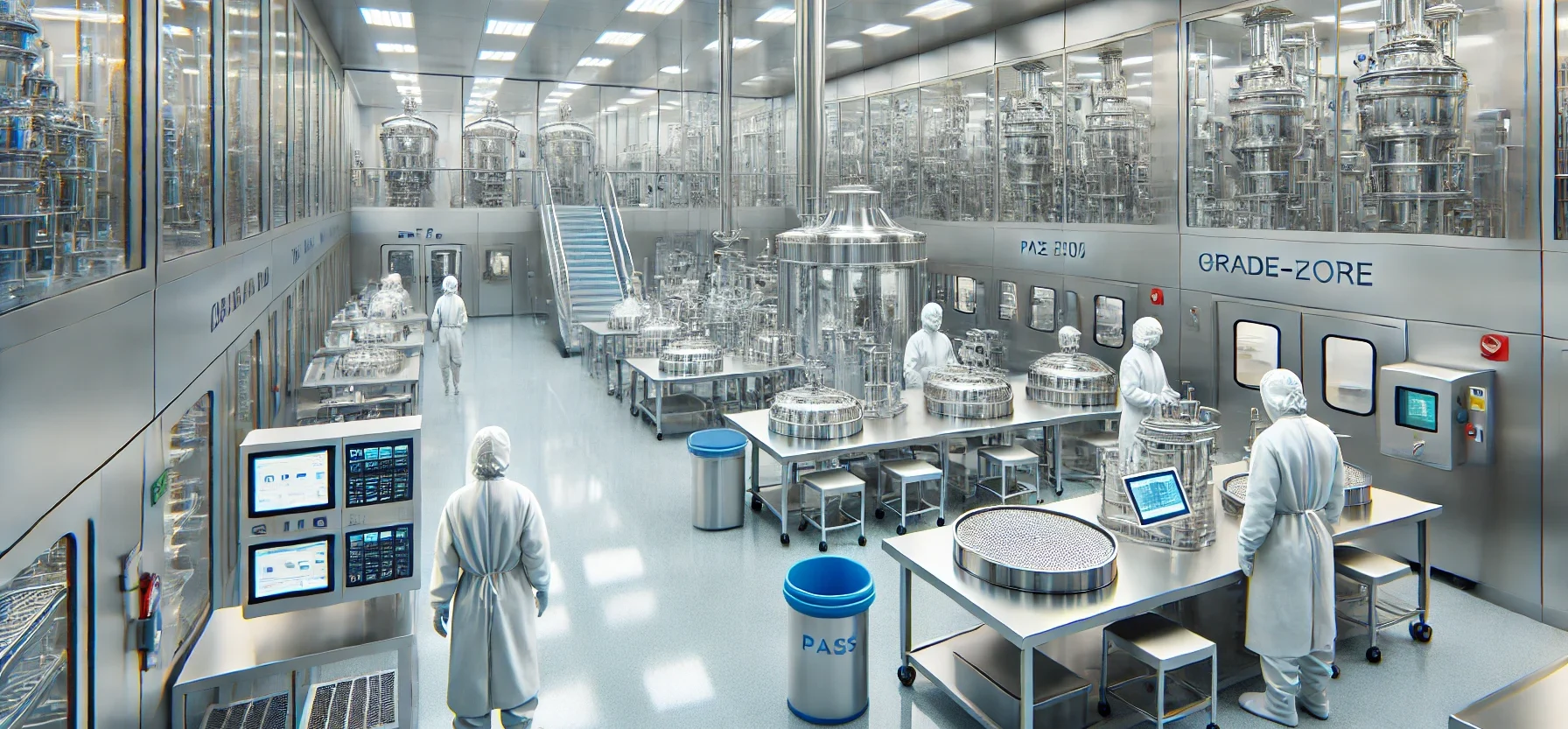

- Designing an aseptic area involves creating a highly controlled environment to prevent contamination in processes such as pharmaceutical manufacturing, healthcare, or lab work.

Key Considerations in Designing of aseptic area

-

Regulatory Compliance:

- Follow guidelines from bodies like FDA, EMA, WHO, and standards like ISO 14644.

-

Cleanroom Classification:

- Define based on maximum particle counts (ISO Class 5-8).

-

Layout and Design:

- Unidirectional Flow: Prevent cross-contamination.

- Zoning: Establish areas with increasing cleanliness levels.

- Airlocks: Maintain pressure differentials.

- Separate Flows: Distinct entry/exit for personnel and materials.

-

HVAC System:

- HEPA Filtration: Remove particulates.

- Air Changes: Ensure adequate air changes per hour (ACH).

- Pressure Control: Positive pressure in clean zones.

- Temperature/Humidity: Maintain specified levels.

-

Surface Materials:

- Use non-porous, smooth, and easily cleanable materials.

- Coving: Smooth transitions at floor-wall junctions.

-

Equipment and Furnishings:

- Choose designs that minimize dust accumulation and are easy to clean.

-

Lighting:

- Sufficient, non-heat-generating, and easy-to-clean lighting.

-

Personnel and Material Handling:

- Gowning Procedures: Strict protocols for personnel.

- Material Transfer: Use sterile techniques.

-

Cleaning and Maintenance:

- Regular, rigorous cleaning and disinfection schedules.

-

Monitoring and Validation:

- Environmental Monitoring: Regular checks for contaminants.

- Validation: Ensure all processes meet cleanliness standards.

Four Main Grades of Cleanrooms

-

Grade A:

- For high-risk operations (e.g., laminar flow hoods).

- Highest cleanliness standards.

-

Grade B:

- Background for Grade A areas.

- Supports aseptic preparation and filling.

-

Grade C:

- Clean areas for less critical stages (e.g., solution preparation).

-

Grade D:

- Areas for final cleaning and preparatory steps.

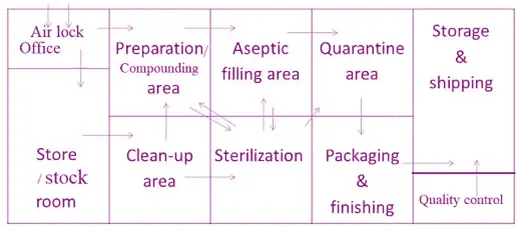

Design Example

Advertisements

Design Example: Floor Plan Layout

- Gowning Area: Area where personnel change into cleanroom attire.

- Airlock: Maintains pressure differentials between zones.

- Aseptic Core Area: Main cleanroom dedicated to critical operations.

- Material Airlock/Pass-Through: Used for decontaminating materials before entry.

- Support Areas: Includes storage and waste management spaces.

Workflow

-

Entry:

- Separate airlocks for personnel and materials.

-

Processing:

- Conducted in aseptic core with strict protocols.

-

Exit:

- Designated routes for personnel and waste.