- Elastic and Plastic Deformation explains temporary vs permanent shape changes in materials under stress.

- Elastic and Plastic Deformation is key in material science for strength, durability, and design.

- When an external force is applied to a solid, it may change shape or size.

- This is called deformation.

- It can be elastic or plastic depending on the extent of the force and the material properties.

- Solids deform in two main ways under stress:

Elastic Deformation

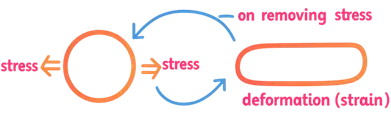

- Definition: A temporary deformation. The material returns to its original shape after removal of stress.

- Cause: Stretching of interatomic bonds.

- Behavior: Linear stress-strain relationship (Hooke’s Law).

- Example in pharmaceutics: Microcrystalline cellulose exhibits predominantly elastic behavior.

Advertisements

Hooke’s Law:

$\sigma = E \cdot \varepsilon$

- Where:

- E = Elastic modulus or Young’s modulus

Advertisements

Plastic Deformation

- Definition: A permanent deformation. The material does not return to its original shape after stress is removed.

- Cause: Irreversible movement of atoms or particles.

- Important in powder compression: Materials must undergo some plastic flow to form solid, coherent tablets.

- Example: Starch and calcium phosphate show more plastic deformation.

Advertisements