- Equipment for Tablet Coating is specialized machinery used to apply a protective or functional layer over tablets. It ensures uniform coating, improves appearance, and controls drug release.

- Equipment for Tablet Coating – Common types include coating pans, fluidized bed coaters, and automated spray systems, each designed to provide consistent and efficient coating under controlled conditions.

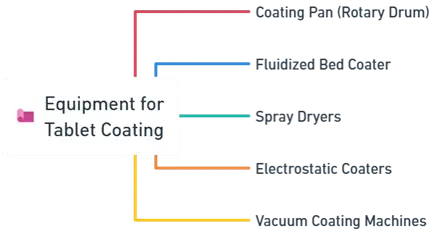

Here are some Equipment for Tablet Coating given below:

Here are some Equipment for Tablet Coating given below:

Coating Pan (Rotary Drum)

- Description: A large, rotating drum where tablets are coated by spraying.

-

Features:

- Adjustable rotation speed.

- Equipped with spray nozzles for even distribution.

- Incorporates drying mechanisms (e.g., hot air).

Fluidized Bed Coater

- Description: A chamber where air is blown upward to fluidize tablets for uniform coating.

-

Features:

- Spray systems for applying the coating solution.

- Heating elements for drying.

- Adjustable air flow and temperature controls.

Spray Dryers

- Description: Equipment that atomizes and dries the coating solution before deposition.

-

Features:

- Atomization nozzles.

- Controlled heating systems.

- Particle collection mechanisms.

Electrostatic Coaters

- Description: Machines that use electrostatic forces to apply coatings.

-

Features:

- Charging systems for tablets and coating particles.

- Controlled spray nozzles.

- Electric field generators.

Vacuum Coating Machines

- Description: Chambers where coating is applied under vacuum conditions.

-

Features:

- Vacuum pumps.

- Vaporization systems for coating materials.

- Temperature and pressure controls.