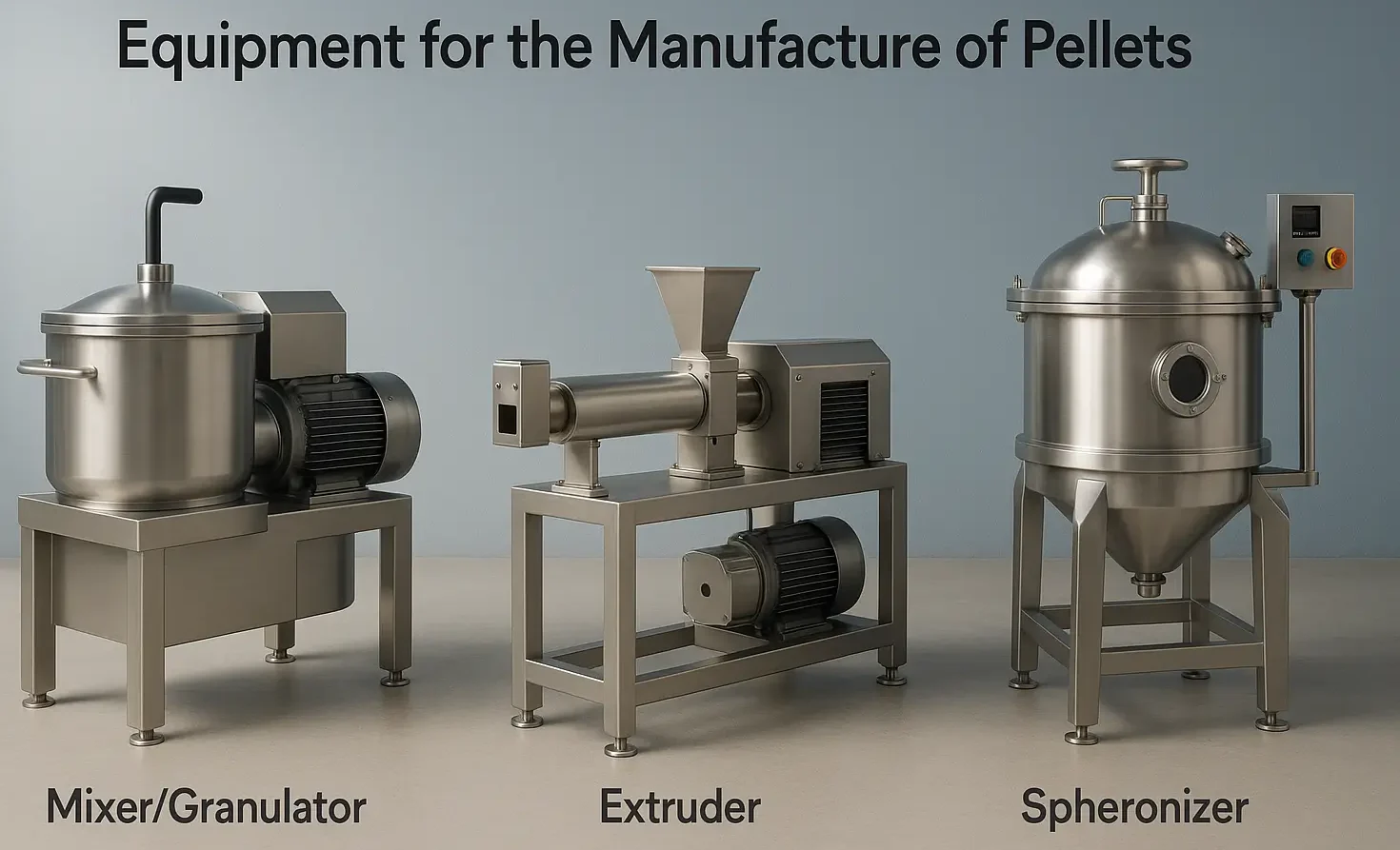

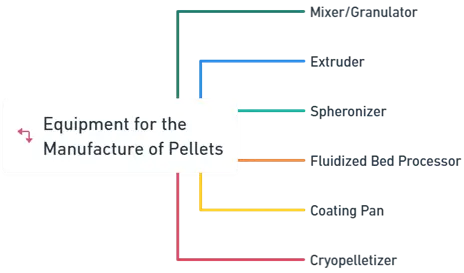

- Equipment for the Manufacture of Pellets involves specialized machinery for producing uniform drug-loaded spheres. It includes mixers, extruders, and spheronizers essential for granulation, shaping, and rounding processes.

- Equipment for the Manufacture of Pellets ensures efficiency, quality, and scalability in pharmaceutical pellet production, meeting dosage uniformity and controlled-release requirements.

- The choice of equipment depends on the pelletization method used. Key machines include:

-

Mixer/Granulator:

- Prepares the wet mass or powder mixture.

- Examples: High-shear mixers, planetary mixers.

-

Extruder:

- Converts the wet mass into cylindrical extrudates.

-

Types:

- Axial Extruder: Extrudate is forced through a die using a screw mechanism.

- Radial Extruder: Extrudate exits radially from a rotating die.

- Basket Extruder: Produces highly uniform extrudates.

-

Spheronizer:

- Rounds the extrudates into spherical pellets.

- Consists of a rotating friction plate and walls to promote rounding through centrifugal and frictional forces.

-

Fluidized Bed Processor:

- Used for layering, drying, or coating pellets.

- Works by suspending pellets in a stream of air and applying coating materials.

-

Coating Pan:

- Used for applying drug or polymer coatings onto pellets.

- Features spray guns and a rotating pan.

-

Cryopelletizer:

- For cryopelletization, where liquid formulations are dropped into a freezing medium like liquid nitrogen.

Click Here to Watch the Best Pharma Videos