- Eutectic Mixture can present challenges during the formulation, compounding, and storage of the final product.

- Eutectic Mixture may also impact the drug release profile, bioavailability, and overall therapeutic efficacy of the final product.

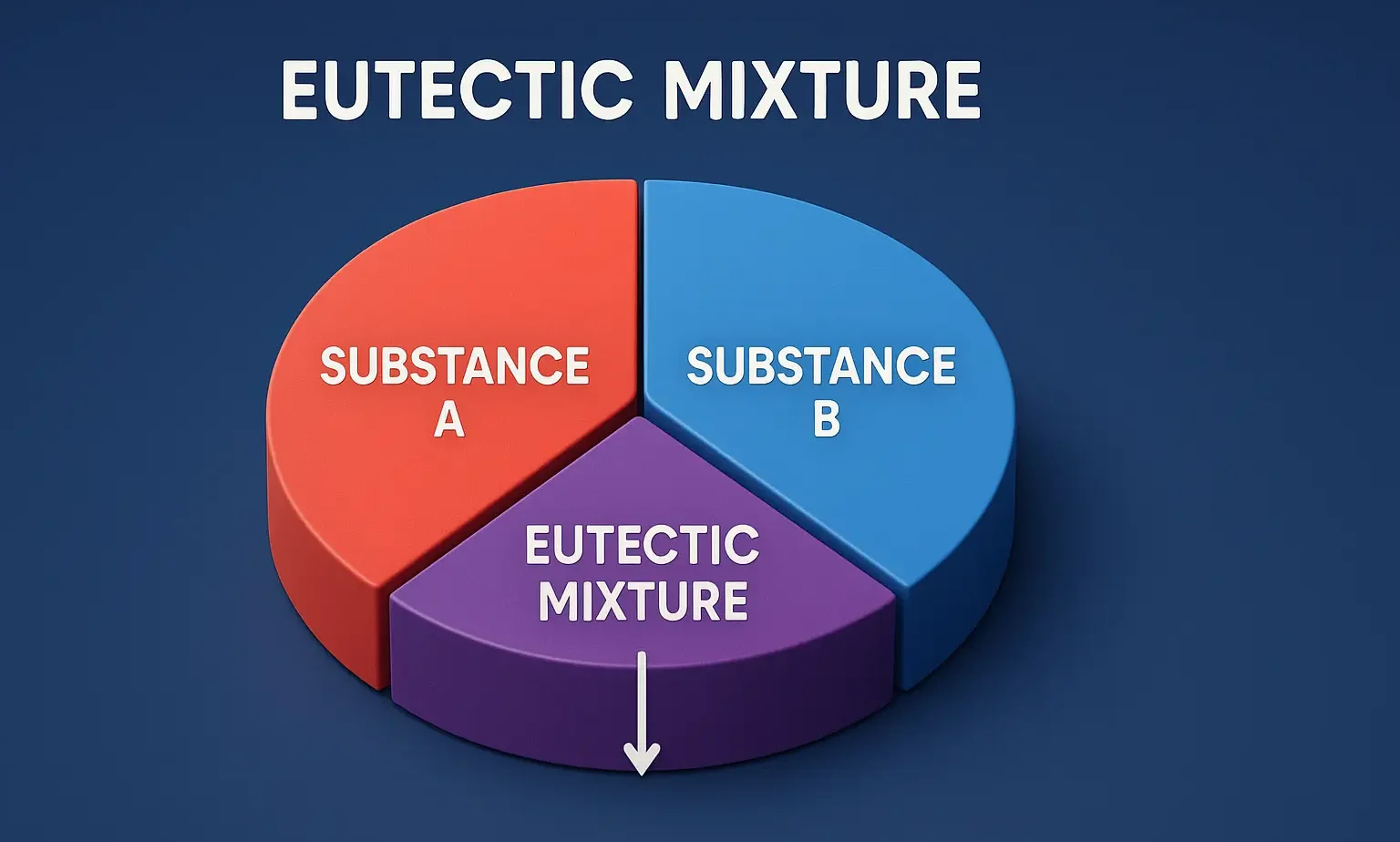

- When two or more components in a powder formulation form a eutectic mixture, they can create a mass that is sticky, pasty, or even liquid-like at or near the eutectic melting point, which is lower than the melting points of the individual components.

- These altered physical properties can cause difficulties in handling, processing, and maintaining the stability of the final powder dosage form.

Strategies to Address Eutectic Mixtures:

-

Physical Separation:

- Microencapsulation can be used to coat one or both components, preventing direct contact and avoiding eutectic formation.

-

Modification of Components:

- Chemical or physical modifications, such as using different salts, polymorphs, or solvates, can alter melting points and reduce eutectic formation.

-

Use of Additives:

- Diluents, stabilizers, or anti-caking agents can help prevent eutectic formation by absorbing moisture, reducing interactions, or altering melting points.

-

Controlled Storage Conditions:

- Temperature and humidity control can help prevent eutectic formation by maintaining storage conditions below the eutectic melting point.

Click Here to Watch the Best Pharma Videos