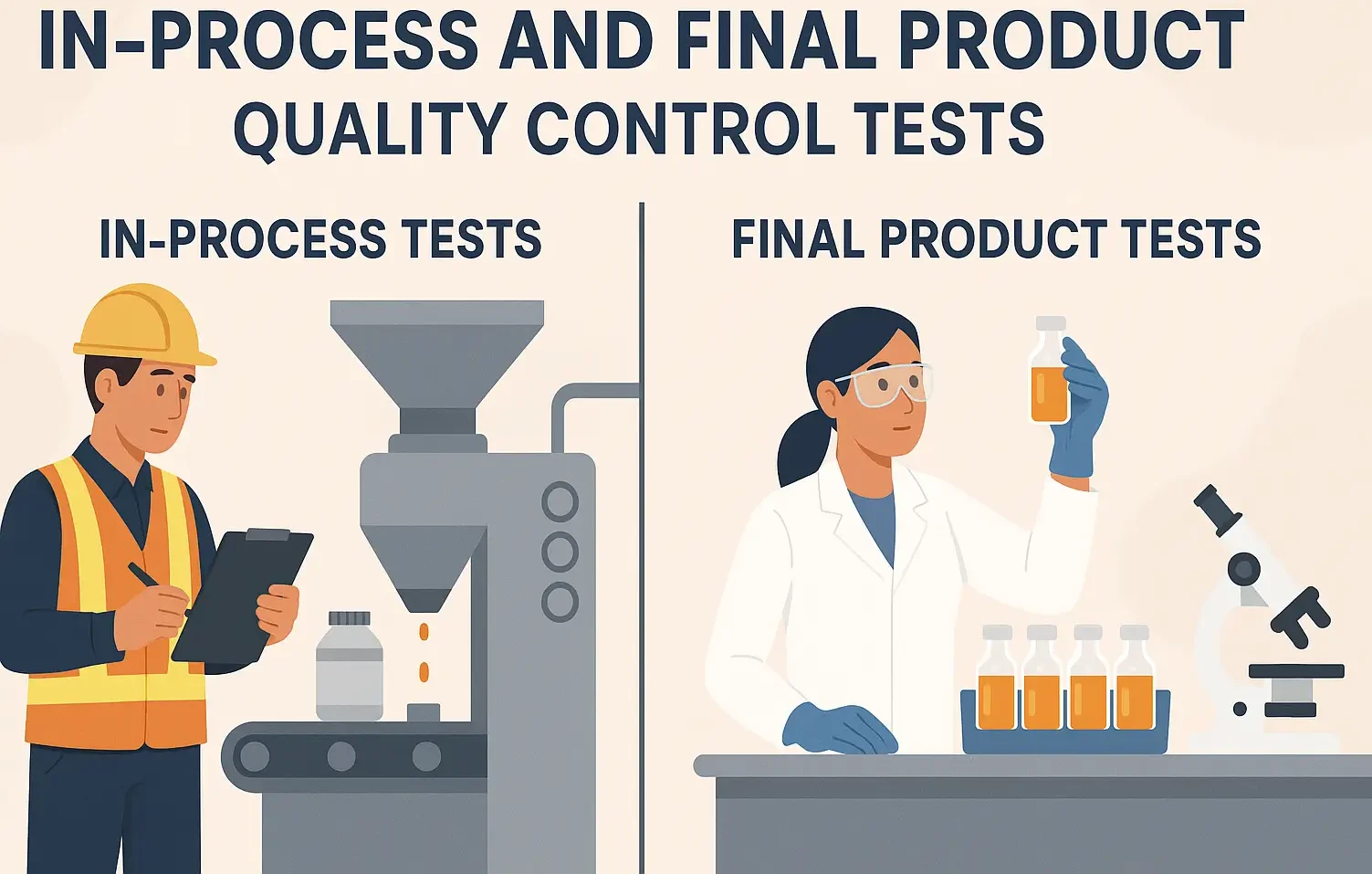

- In-Process and Final Product Quality Control Tests are essential for ensuring pharmaceutical product quality.

- In-Process and Final Product Quality Control Tests check parameters during manufacturing process and confirm safety, efficacy, and compliance before release.

In-Process Quality Tests:

-

Weight Variation:

- Ensures consistent weight across capsules.

- Conducted by weighing individual capsules and comparing with average weight.

-

Moisture Content:

- Measured to ensure capsules are neither too brittle nor too soft.

-

Appearance:

- Visual inspection for uniformity in color, size, and absence of defects.

Final Product Quality Control Tests:

-

Disintegration Test:

- Determines the time required for capsules to break down in a specified medium (usually simulated gastric or intestinal fluids).

-

Dissolution Test:

- Measures the rate and extent of drug release from the capsule.

-

Content Uniformity:

- Ensures uniform drug distribution within capsules.

-

Stability Testing:

- Capsules are subjected to accelerated and long-term stability studies under varying conditions (temperature, humidity) to assess product shelf life.

-

Microbial Testing:

- Evaluates the microbial load to ensure the absence of harmful bacteria or fungi.

-

Seal Integrity:

- For liquid-filled capsules, checks for leaks or breaches in the capsule shell.

Click Here to Watch the Best Pharma Videos