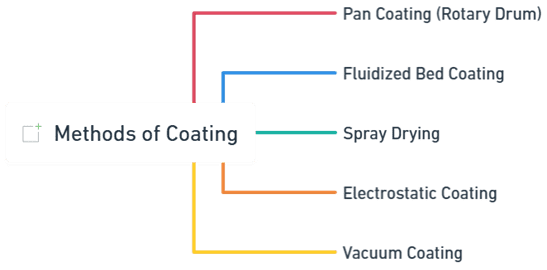

- Methods of Coating are essential in pharmaceutical and industrial processes for enhancing product quality and functionality.

- Methods of coating refer to various techniques used to apply a thin layer of material onto the surface of solids like tablets or granules to protect, mask taste, control release, or enhance appearance and stability in pharmaceutical and industrial applications.

1. Pan Coating (Rotary Drum):

- Process: Tablets rotate in a drum while coating solution is sprayed and dried.

- Advantages: Simple, widely used, works for aqueous and non-aqueous coatings.

- Disadvantages: Limited thickness control, risk of uneven coating in large batches.

2. Fluidized Bed Coating:

- Process: Tablets are suspended in an air stream, sprayed with coating, and dried simultaneously.

- Advantages: Uniform coating, precise thickness control, energy-efficient drying.

- Disadvantages: Expensive equipment, risk of tablet breakage.

Advertisements

3. Spray Drying:

- Process: Coating is atomized into droplets, dried, and adhered to tablets.

- Advantages: Rapid drying, suitable for heat-sensitive drugs.

- Disadvantages: High energy use, limited scalability.

4. Electrostatic Coating:

- Process: Tablets and coating particles are charged electrostatically for even application.

- Advantages: Precise coating, minimal waste.

- Disadvantages: Requires specialized equipment, less common for large batches.

5. Vacuum Coating:

- Process: Coating materials are vaporized and deposited in a vacuum chamber.

- Advantages: Solvent-free, uniform coating.

- Disadvantages: High cost, limited scalability.