- Methods of Preparation of Ophthalmic involve aseptic compounding under sterile conditions to prevent contamination and ensure patient safety.

- Methods of Preparation of Ophthalmic vary for drops, ointments, and gels, requiring precise formulation, pH adjustment, and isotonicity.

-

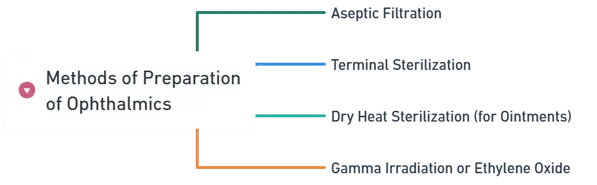

Aseptic Filtration:

- The formulation (solution) is passed through a sterile 0.22 μm membrane filter, removing bacteria and other particulates.

- The filtered solution is then filled into previously sterilized containers under laminar airflow conditions.

-

Terminal Sterilization:

- If the formulation and container can withstand heat, autoclaving at 121°C for 15–20 minutes is often employed.

- Advantages: higher sterility assurance level.

- Disadvantages: not suitable for heat-labile drugs.

-

Dry Heat Sterilization (for Ointments):

- The base can be sterilized by heating in an oven at 160–170°C for a specific time.

- Drug powders might be sterilized separately if stable to heat, then mixed under aseptic conditions.

-

Gamma Irradiation or Ethylene Oxide:

- Used in specialized cases (e.g., certain packaging materials).

- Less common for routine ophthalmic solutions due to potential effects on drug stability and safety.

Click Here to Watch the Best Pharma Videos!