- Modern Methods of Extraction is the first crucial step in phytochemical analysis, aiming to isolate bioactive compounds from plant material.

- Modern extraction methods focus on improving efficiency, reducing solvent usage, and preserving compound integrity.

Conventional Extraction Techniques

- Conventional methods have been used for a long time and rely primarily on heat and solvent use to extract bioactive compounds.

- These methods are widely accepted due to their simplicity, but they often require longer extraction times and large amounts of solvents.

-

Maceration

- Maceration is a simple extraction technique where the plant material is soaked in a solvent for a specified period to dissolve bioactive compounds.

Construction & Apparatus:

- A container (glass or stainless-steel vessel) with a wide mouth.

- Solvent (such as ethanol, methanol, or water).

- Filtration apparatus (such as filter paper or a mesh strainer).

Procedure/Working:

- The plant material is finely powdered or cut into small pieces to increase the surface area.

- The material is soaked in an appropriate solvent (like ethanol or water).

- The mixture is kept at room temperature for 1–3 days, stirred occasionally.

- The liquid extract is filtered to separate the solvent from the plant residue.

- The solvent is evaporated to obtain the concentrated extract.

Advantages:

- Simple, cost-effective, and does not require special equipment.

Disadvantages:

- Slow, requires large amounts of solvent, and has low efficiency.

-

Percolation

- Percolation is a continuous process where fresh solvent passes through a column packed with plant material to ensure efficient extraction.

Construction & Apparatus:

- Percolator (a cylindrical vessel with a perforated bottom).

- Solvent (ethanol, methanol, or water).

- Collection flask to gather the extract.

Procedure/Working:

- The finely powdered plant material is moistened with the solvent and placed in a percolator.

- The solvent is added gradually to allow thorough saturation.

- The percolator is kept for 24 hours, allowing the solvent to dissolve the bioactive compounds.

- The extract is collected dropwise from the percolator.

- The extract is concentrated by evaporation.

Advantages:

- Continuous extraction, efficient use of solvent, and faster than maceration.

Disadvantages:

- Requires more apparatus, and solvent selection is crucial.

-

Soxhlet Extraction

- Soxhlet extraction is a more efficient conventional method that uses continuous recycling of the solvent to extract bioactive compounds.

Construction & Apparatus:

- Soxhlet extractor (a glass apparatus with a siphon and thimble holder).

- Round-bottom flask (for holding the solvent).

- Reflux condenser (to condense and recycle solvent).

- Solvent (ethanol, methanol, hexane, etc.).

Procedure/Working:

- The dried plant material is placed inside a thimble in the Soxhlet extractor.

- The solvent is heated in the round-bottom flask to produce vapors.

- The vapors rise and condense in the reflux condenser.

- The condensed solvent continuously percolates through the plant material, extracting bioactive compounds.

- Once the cycle is complete, the solvent is evaporated to concentrate the extract.

Advantages:

- Efficient, extracts more bioactive compounds, and requires less solvent compared to maceration.

Disadvantages:

- High temperature may degrade heat-sensitive compounds, and the process requires a long extraction time.

Modern Extraction Techniques

- Modern methods of extraction are developed to overcome the limitations of conventional methods.

- These techniques enhance efficiency, reduce solvent usage, and ensure better preservation of bioactive compounds.

-

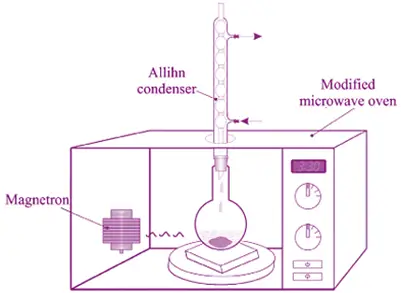

Microwave-Assisted Extraction (MAE)

- This method uses microwave energy to accelerate the extraction process by increasing the temperature and pressure inside the extraction vessel.

Procedure/Working:

- The plant material is placed in a microwave-transparent vessel.

- The solvent (ethanol, water, or acetone) is added to cover the material.

- The system is exposed to microwave radiation, which heats the solvent and breaks the plant cell walls.

- The extract is collected and filtered to separate the solid and liquid phases.

- The solvent is evaporated to obtain the final extract.

Advantages:

- Rapid extraction, energy-efficient, and less solvent consumption.

Disadvantages:

- High heat may degrade sensitive compounds, and specialized equipment is required.

-

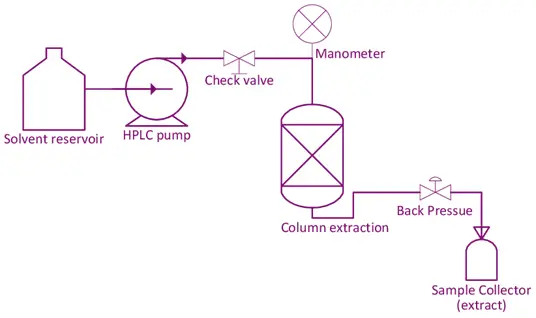

Pressurized Liquid Extraction (PLE) (Accelerated Solvent Extraction)

- PLE uses high pressure and temperature to enhance the extraction efficiency while minimizing solvent usage.

Procedure/Working:

- The plant material is loaded into a high-pressure extraction chamber.

- A suitable solvent (ethanol, methanol, or water) is introduced.

- The chamber is heated to 50–200°C and pressurized (10–15 MPa).

- The increased temperature and pressure improve the solubility and diffusion of bioactive compounds.

- The extract is collected and filtered to obtain the final concentrated solution.

Advantages:

- High efficiency, less solvent required, and better compound recovery.

Disadvantages:

- Expensive equipment and requires precise control of pressure and temperature.