Principles of Paddles:

- This mixers operate on the principle of convective mixing.

- It move through the material, pushing and folding it to achieve thorough mixing.

- This type of mixing is gentle and suitable for materials that are sensitive to shear.

Construction of Paddles:

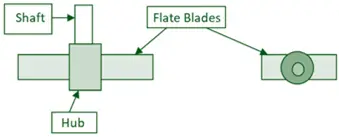

- Paddles: Large flat or curved blades mounted on a central shaft.

- Shaft: Central shaft that holds the paddles.

- Drive System: Motor and gearbox to rotate the shaft and paddles.

- Vessel: U-shaped or cylindrical container that holds the material to be mixed.

- Support Frame: Sturdy frame to hold the vessel and drive system.

Working:

- Materials are loaded into the vessel.

- The paddles rotate, moving through the materials and creating a mixing action.

- This rotation lifts and folds the materials, ensuring thorough mixing.

- Mixing continues until the desired homogeneity is achieved.

- The mixed product is discharged through a bottom valve or port.

Advertisements

Uses:

- Food Industry: Mixing dough, cereals, and dry powders.

- Pharmaceuticals: Blending powders and granules.

- Chemical Industry: Mixing fine chemicals and dry materials.

Merits:

- Gentle mixing action, suitable for delicate materials.

- Simple design and operation.

- Can handle a wide range of viscosities.

- Low energy consumption.

Demerits:

- Less efficient for very fine powders or materials with significant density differences.

- May not provide adequate mixing for high-shear applications.

- Limited to batch processing.