- Pelletization is the process of converting fine powders or granules into small, free-flowing, spherical units.

- Pelletization Process can be achieved through various techniques:

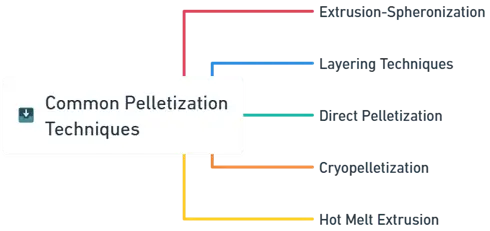

Common Pelletization Techniques:

-

Extrusion-Spheronization:

- The most widely used method for producing pellets.

-

Steps:

- Mixing and Wet Massing: The drug and excipients are blended, and a binder solution is added to form a wet mass.

- Extrusion: The wet mass is passed through an extruder to form cylindrical extrudates.

- Spheronization: The extrudates are broken into smaller units and rounded into spherical pellets in a spheronizer.

- Drying: The pellets are dried to reduce moisture content.

-

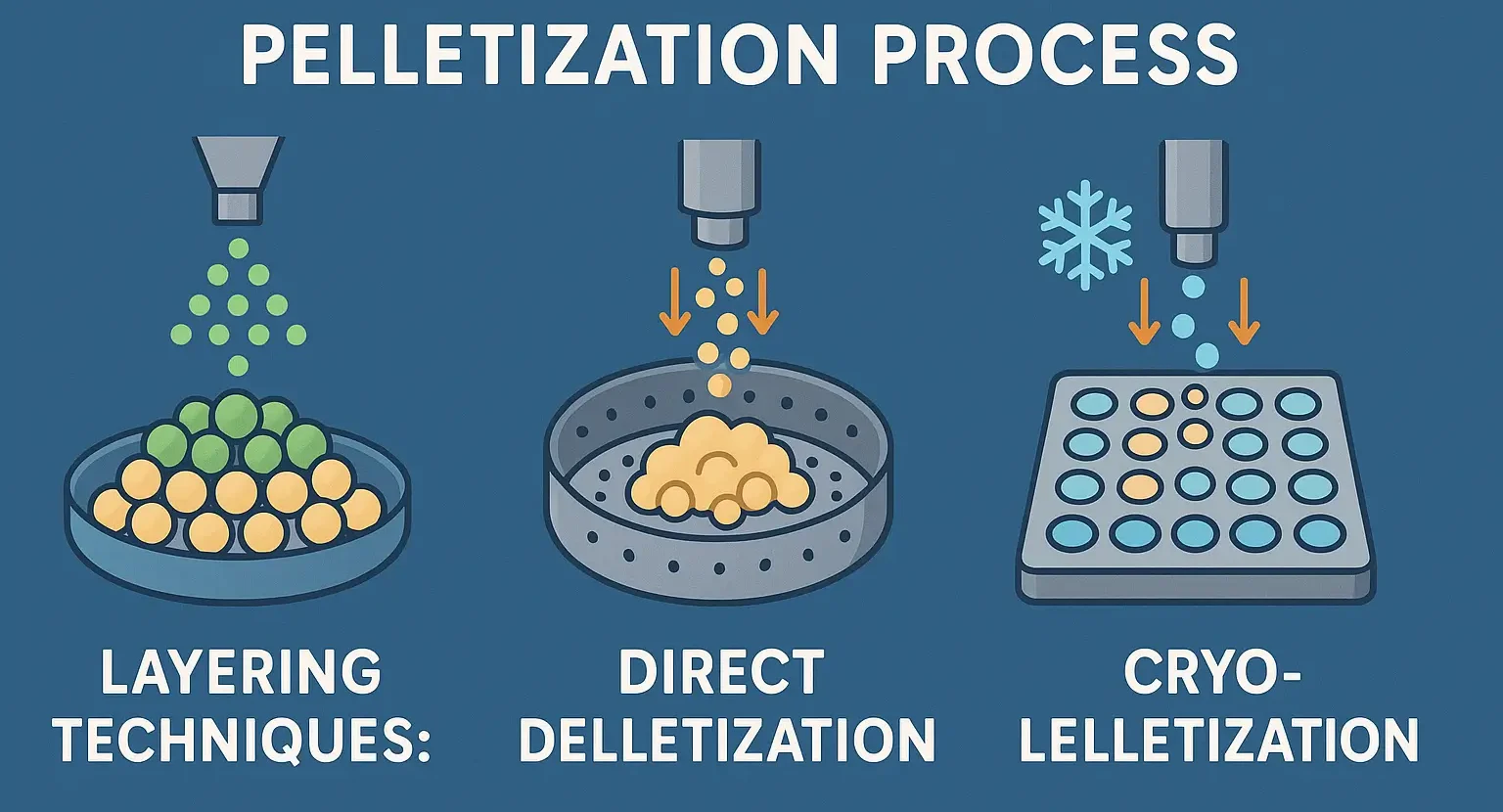

Layering Techniques:

- Used to apply layers of drug or excipients onto an inert core.

-

Types:

- Solution/Suspension Layering: A solution or suspension of the drug is sprayed onto the cores while rotating in a pan or fluidized bed.

- Powder Layering: Dry powder is layered onto cores, followed by binder spraying.

-

Direct Pelletization:

- Involves forming pellets directly from powders in high-shear granulators or fluidized bed processors without the extrusion step.

- Often requires specialized excipients like MCC.

-

Cryopelletization:

- Used for temperature-sensitive drugs.

- The liquid formulation is dropped into liquid nitrogen, forming frozen pellets.

-

Hot Melt Extrusion:

- Suitable for drugs with poor water solubility.

- The drug and polymer are melted and extruded to form pellets.

Click Here to Watch the Best Pharma Videos