- Production of Hard gelatin capsules shells involves dipping stainless steel pins into a gelatin solution to form capsule halves.

- Production of Hard Gelatin Capsule Shells – Precise control in viscosity, temperature, and drying ensures consistent capsule quality for pharmaceutical use.

- The manufacturing of empty hard gelatin capsule shells is a specialized process often done on an industrial scale by capsule suppliers.

Raw Materials used in Production of Hard Gelatin Capsule Shells:

- Gelatin: Derived from animal collagen (commonly bovine or porcine sources), gelatin provides the structural matrix.

- Plasticizers: Substances like glycerin or sorbitol are added to enhance flexibility and prevent brittleness.

- Water: Acts as a solvent and plasticizer.

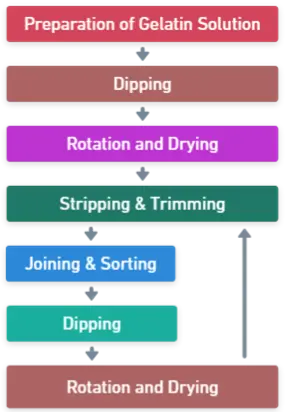

Manufacturing Process:

The manufacturing process of empty hard gelatin capsule shells involves the following steps:

Advertisements

-

Preparation of Gelatin Solution

- Gelatin Source: Derived from partial hydrolysis of collagen (Type A: acid treatment; Type B: alkali treatment).

- Ingredients: Gelatin (20–30

- Control: Temperature (50–60 °C) and viscosity are maintained for uniform wall thickness.

-

Dipping

- Pins/Molds: Stainless steel pins (different diameters for body and cap) are dipped into the gelatin solution.

- Depth & Time: Dipping depth and residence time control shell thickness.

-

Rotation and Drying

- Rotation: Pins are rotated to evenly distribute the gelatin film.

- Drying: Pins pass through drying tunnels (20–25 °C, 40–50

-

Stripping & Trimming

- Dried shells are stripped off the pins and cut to the desired length for body and cap sections.

-

Joining & Sorting

- Body and cap are loosely joined to form a two-piece capsule, and defective shells are removed

Advertisements