Principles of Propellers:

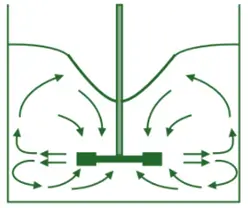

- Propeller mixers operate on the principle of creating axial and radial flow patterns in liquids.

- The propeller blades create a vortex that circulates the liquid, promoting thorough mixing.

Construction of Propellers:

- Propeller Blades: Three or more angled blades mounted on a central shaft.

- Drive System: Includes a motor and gearbox to rotate the propeller.

- Mounting: Can be mounted on the top, side, or bottom of the mixing vessel.

- Mixing Vessel: A container that holds the liquid to be mixed.

Working:

- The propeller is submerged in the liquid to be mixed.

- When the propeller rotates, it creates a vortex, drawing the liquid from the top and pushing it downward.

- This circulation pattern ensures thorough mixing of the liquid throughout the vessel.

- Mixing continues until the desired homogeneity is achieved.

Advertisements

Uses:

- Chemical Industry: Mixing solutions, suspensions, and emulsions.

- Water Treatment: Ensuring uniform distribution of chemicals in water.

- Food Industry: Blending beverages, syrups, and other liquid ingredients.

Merits:

- Efficient for low to medium viscosity liquids.

- Simple design and easy to operate.

- Can be used for continuous mixing.

- Low energy consumption compared to other mixers.

Demerits:

- Not suitable for high-viscosity materials.

- Limited shear force, which may be insufficient for certain applications.

- Propeller blades can cause foaming in some liquids.