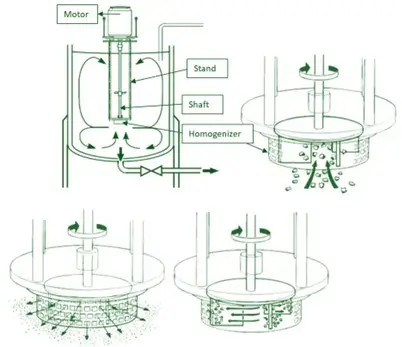

Principle of Silverson Emulsifier:

- The Silverson emulsifier operates on the principle of high-shear mixing.

- It uses a rotor-stator mechanism to create intense shear forces that emulsify, homogenize, and mix materials efficiently.

Construction of Silverson Emulsifier:

- Rotor: High-speed rotating element.

- Stator: Stationary element with perforations or slots.

- Drive System: Motor to drive the rotor.

- Mixing Head: Encloses the rotor and stator and is designed to handle high shear forces.

- Support Frame: Holds the emulsifier in place.

Working:

- Materials are drawn into the mixing head by the high-speed rotation of the rotor.

- The rotor forces the materials through the stator’s perforations, creating intense shear forces.

- This action breaks down particles, disperses them uniformly, and forms stable emulsions.

- The emulsified product is discharged through the outlet.

Advertisements

Uses:

- Pharmaceuticals: Emulsifying creams, ointments, and suspensions.

- Food Industry: Creating emulsions like mayonnaise and salad dressings.

- Cosmetics: Blending lotions, creams, and gels.

- Chemical Industry: Preparing fine emulsions and dispersions.

Merits:

- Extremely efficient at creating stable emulsions and dispersions.

- High shear forces ensure rapid and thorough mixing.

- Suitable for both batch and continuous processing.

- Capable of handling a wide range of viscosities and materials.

Demerits:

- High energy consumption.

- Can generate significant heat, which may affect temperature-sensitive materials.

- Requires thorough cleaning, especially for sticky or viscous materials.

- Potential for wear and tear due to high-speed operation.