Principles of Tray Dryer

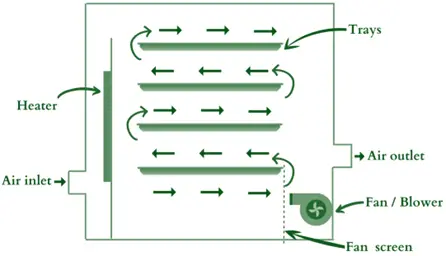

- A tray dryer operates on the principle of convection drying, where heated air circulates over the trays containing the wet material.

- The moisture from the material is transferred to the air and carried away, leaving the material dry.

Construction of Tray Dryer

Advertisements

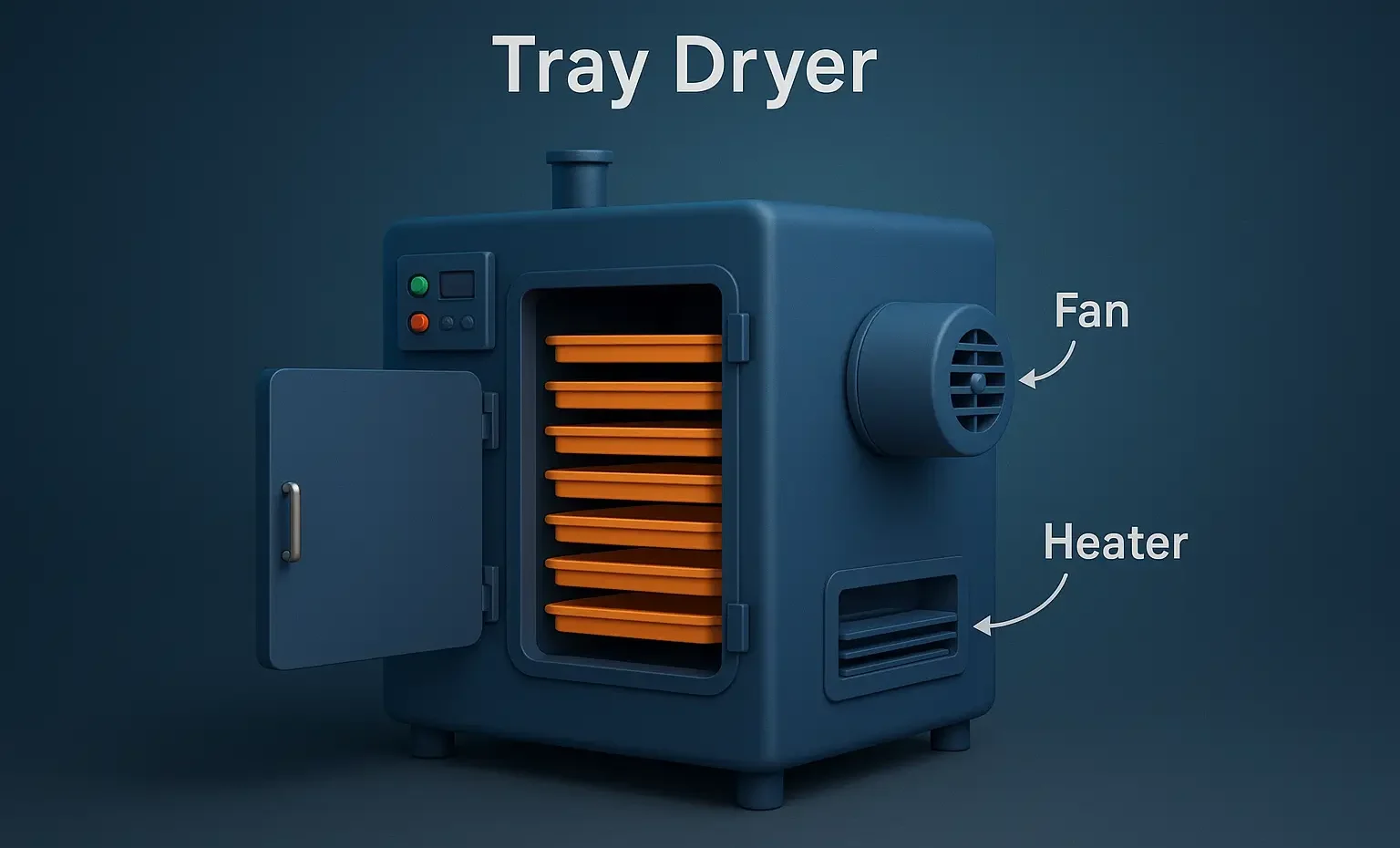

- Chamber: An insulated enclosure to maintain heat.

- Trays: Perforated trays hold the material to be dried, allowing air to pass through.

- Heating System: Heaters (electric, steam, or gas) provide the necessary heat.

- Air Circulation: Fans circulate hot air to ensure uniform drying.

- Exhaust System: Removes moist air from the chamber.

Working of Tray Dryer

- Loading: Material is spread evenly on the trays.

- Heating: Heaters raise the temperature inside the chamber.

- Air Circulation: Fans circulate hot air over the material.

- Moisture Removal: Moist air is exhausted out of the chamber.

- Monitoring: Temperature and humidity are monitored and controlled.

Advertisements

Uses

- Drying pharmaceuticals, food products, chemicals, and powders.

Merits

- Uniform Drying: Even distribution of heat and air.

- Simple Operation: Easy to operate and maintain.

- Versatility: Suitable for a wide range of materials.

Advertisements

Demerits

- Slow Process: Can be slower compared to other drying methods.

- Labor Intensive: Requires manual loading and unloading.

- Energy Consumption: Can be energy intensive.