- The valves regulate the release of the formulation and ensures accurate dosing.

Components of a Valve System:

- Valve Cup: Secures the valve to the container.

- Gasket: Prevents leakage and ensures a tight seal.

- Actuator: The part pressed by the user to release the product.

- Stem: Serves as the channel for the product to travel during actuation.

- Spring: Returns the valve to the closed position after use.

- Valve Body: Encases the valve mechanism.

- Dip Tube: Extends into the container, drawing the formulation into the valve for dispensing.

Advertisements

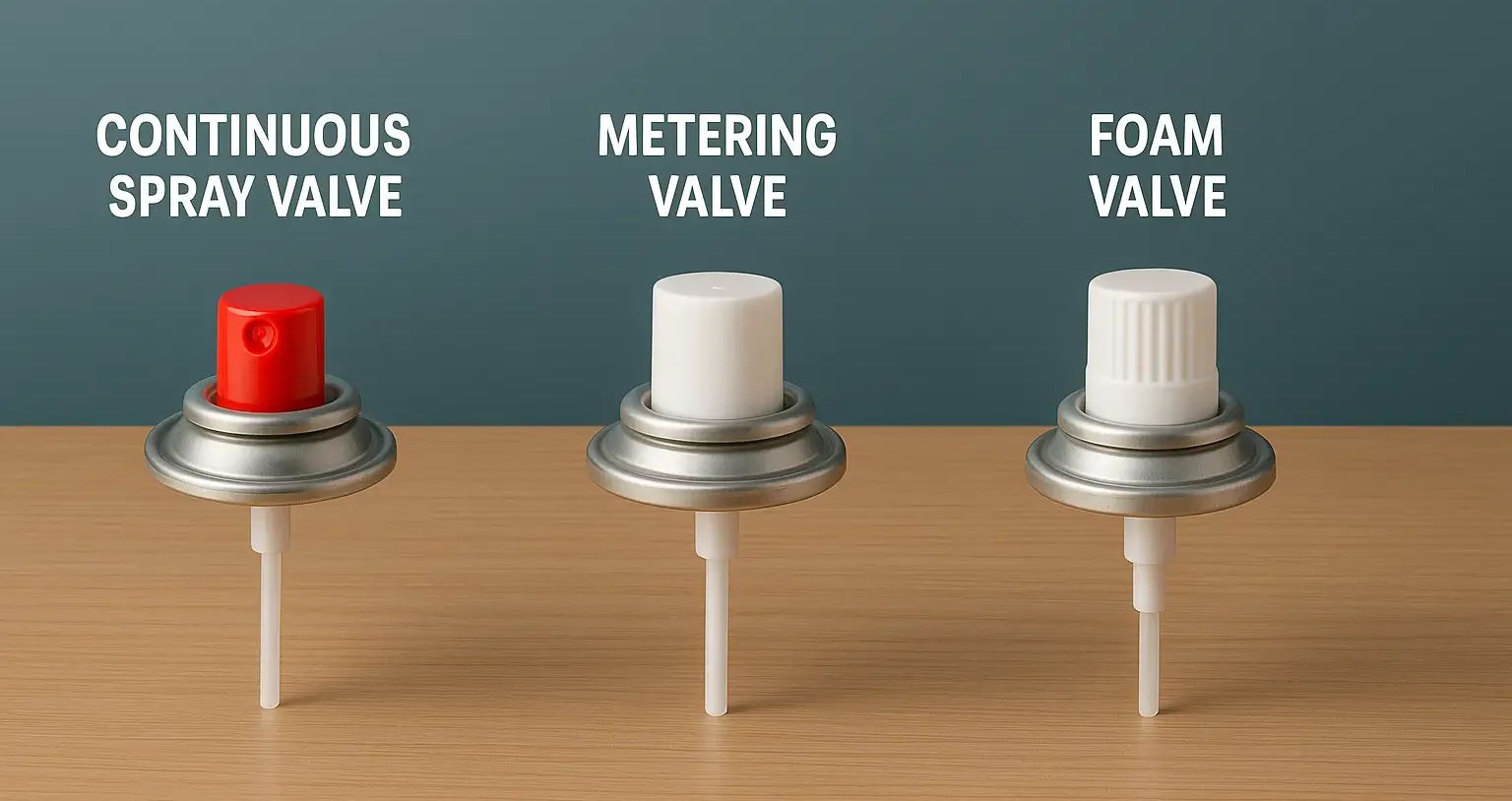

Types of Valves:

-

Continuous Spray Valves

- Allows product to flow as long as the actuator is pressed.

- Common for topical sprays like hair sprays, disinfectants.

-

Metering Valves

- Delivers a specific quantity of product per actuation.

- Critical for inhalation aerosols where dose accuracy is paramount.

-

Foam Valve

- Designed to create and expel foam. Usually paired with specific formulations that contain surfactants.

Advertisements

Desired Valve Properties:

- Good sealing to prevent leaks.

- Chemical compatibility with formulation and propellant.

- Consistent dose accuracy and spray characteristics over product shelf life.

Click Here to Watch the Best Pharma Videos

Advertisements