Principle of Venturimeter:

- Based on Bernoulli’s theorem. The fluid’s velocity increases, and pressure decreases as it passes through the throat of the Venturimeter.

Formula:

$Q = C_d A_1 \sqrt{\frac{2\Delta P}{\rho \left(1 – \left(\frac{A_2}{A_1}\right)^2 \right)}}$

- Where:

- Q = flow rate

- Cd = discharge coefficient

- A1 = cross-sectional area of the pipe before the converging section

- A2 = cross-sectional area of the throat

- ΔP = pressure difference between the inlet and the throat

- ρ = fluid density

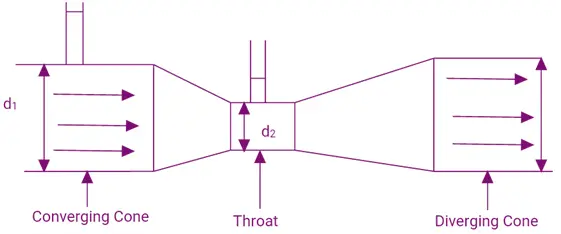

Construction of Venturimeter:

- Converging Section: Narrows the fluid flow.

- Throat: The narrowest section where velocity is highest, and pressure is lowest.

- Diverging Section: Gradually returns the pipe to its original diameter.

- Pressure Taps: Located before the converging section and at the throat.

Working of Venturimeter:

- Fluid enters the Venturimeter and is accelerated in the converging section.

- Maximum velocity and minimum pressure occur at the throat.

- Pressure recovery occurs in the diverging section.

- The pressure difference between the inlet and throat is measured to calculate the flow rate.

Advertisements

Uses:

- Measurement of flow rates in large pipelines.

- Common in water supply systems, gas pipelines, and in various industrial processes.

Advantages:

- High accuracy and reliability.

- Low permanent pressure loss compared to orifice meters.

- Suitable for a wide range of fluid types, including dirty or sediment-laden fluids.

Disadvantages:

- More expensive and complex to install.

- Requires a longer straight pipe section upstream and downstream for accurate measurements.

- Bulky and not suitable for small-diameter pipes.