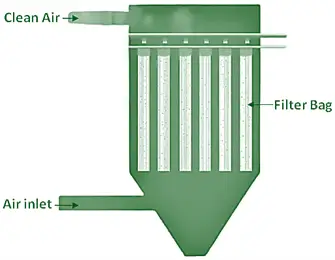

Principles of Bag Filter:

- Separates particles from a gas stream by passing the stream through filter bags. Particles are trapped on the surface of the bags, and clean gas exits the system.

Construction of Bag Filter:

- Filter Bags: Made from woven or felted fabric.

- Housing: Encloses the filter bags and supports the gas flow system.

- Inlet and Outlet: For the gas stream.

- Cleaning System: Mechanisms for periodically removing trapped particles from the bags (e.g., shaking, reverse air flow, pulse jet cleaning).

Working of Bag Filter:

- The gas-particle mixture enters the baghouse.

- Gas passes through the filter bags, trapping particles on the bag surfaces.

- Clean gas exits through the outlet.

- Periodic cleaning removes the trapped particles, which fall into a collection hopper.

Advertisements

Uses:

- Dust collection in industrial processes like cement manufacturing, metalworking, and woodworking.

- Pollution control in power plants and chemical industries.

Merits:

- High collection efficiency for fine particles.

- Can handle large volumes of gas.

- Flexible design for various industrial applications.

Demerits:

- Regular maintenance required to clean and replace bags.

- High operational costs due to frequent cleaning and replacement.

- Pressure drop can be significant, requiring additional energy.