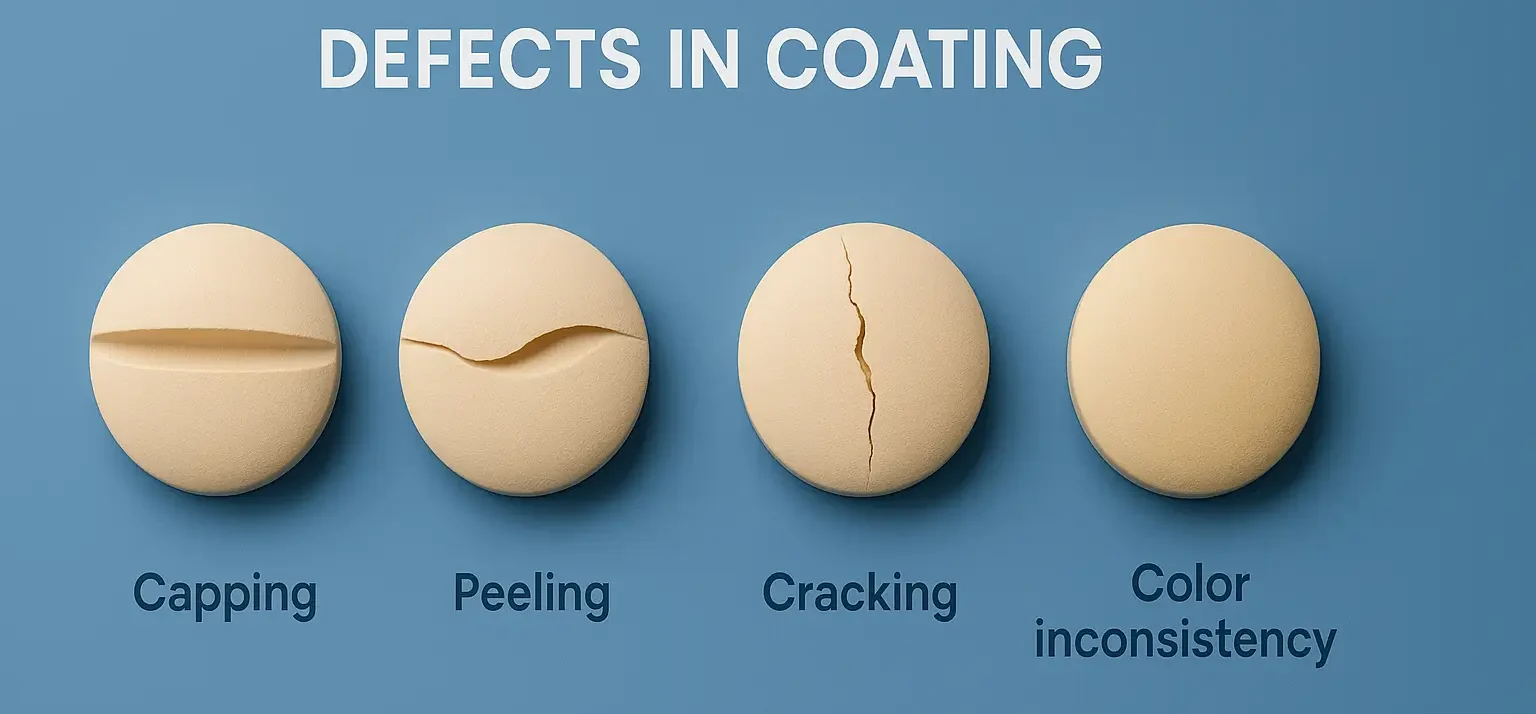

- Defects in Coating refer to imperfections like peeling, cracking, or capping that affect tablet appearance or functionality.

- These result from formulation errors, equipment issues, or process deviations.

- It compromises product quality, stability, and patient acceptability.

- Several problems can occur during the process, affecting the tablet’s appearance, performance, and patient acceptability.

Common Coating Defects:

- Capping: Partial or complete separation of the coating from the tablet.

- Peeling: Large sections of coating detach, exposing the tablet.

- Cracking: Visible cracks in the coating film, potentially affecting integrity.

- Streaking: Uneven color distribution, resulting in visible streaks.

- Mottling: Irregular coloration or blotches due to inconsistent spray or drying.

- Pick-Up: Excess coating material adheres to non-tablet surfaces within the equipment.

- Weight Variation: Inconsistent coating thickness leads to weight discrepancies.

- Color Inconsistency: Variations in color intensity or hue across batches.

Causes of Coating Defects:

- Inadequate Mixing: Poor distribution of coating solution.

- Incorrect Solvent Evaporation: Excess moisture or incomplete drying.

- Temperature Fluctuations: Overheating or insufficient heating affecting polymer properties.

- High Humidity: Moisture affecting the drying process and coating adhesion.

- Improper Equipment Parameters: Incorrect spray rates, air flow, or rotation speed.

- Tablet Surface Issues: Rough or uneven tablet surfaces hinder uniform coating.

- Excessive Coating Thickness: Leads to cracking or capping.

Click Here to Watch the Best Pharma Videos