- Production of Soft Gelatin Capsules ensures precise dosing, improved bioavailability, and enhanced stability of sensitive formulations.

- It ensures precise dosing, improved bioavailability, and enhanced stability of sensitive formulations.

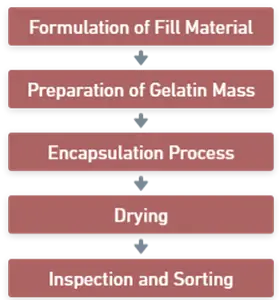

- The production of soft gelatin capsules involves the following steps:

-

Formulation of Fill Material:

-

Preparation of Gelatin Mass:

- Gelatin, plasticizers, and other components are mixed with water and heated under vacuum to remove air bubbles.

- The gelatin mass is held at a controlled temperature (~50°C) to maintain its fluidity.

-

Encapsulation Process:

- The encapsulation is typically performed using a rotary die process:

- Two ribbons of gelatin are formed and fed into the rotary die machine.

- The fill material is injected between the ribbons.

- The ribbons are sealed and cut into individual capsules.

-

Drying:

- Capsules are tumbled in rotating drums to remove excess moisture.

- Further drying occurs in controlled drying tunnels with regulated temperature (20-25°C) and humidity (20-30

-

Inspection and Sorting:

- Capsules are visually inspected for defects like leaks, cracks, or improper sealing.

Advertisements

Click Here to Watch the Best Pharma Videos