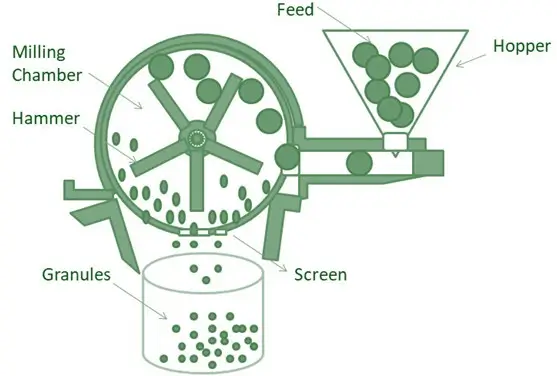

Principle of Hammer Mill:

- Operates on the principle of impact and attrition.

- Material is fed into a grinding chamber where it is struck by hammers attached to a rotating shaft, resulting in size reduction through impact and shearing forces.

Construction of Hammer Mill:

- Grinding Chamber: Cylindrical chamber where material is introduced.

- Hammers: Swinging or fixed blades attached to a rotating shaft.

- Screen: Perforated metal sheet allowing only particles of desired size to pass.

- Feed Mechanism: Hopper for material input.

- Discharge Mechanism: Outlet for processed material.

Working of Hammer Mill:

- Material is fed into the chamber and struck by rapidly rotating hammers.

- Size reduction occurs by impact and attrition.

- Desired particle size is achieved by passing through the screen.

- Processed material exits through the discharge mechanism.

Uses:

- Size reduction of a wide range of materials including grains, spices, pharmaceuticals, and chemicals.

Merits:

- Simple and robust construction.

- High throughput and efficiency.

- Capable of handling a wide variety of materials.

Demerits:

- High noise levels.

- Potential for high heat generation.

- Wear and tear of hammers and screens.

Thank you for reading from Firsthope's notes, don't forget to check YouTube videos!