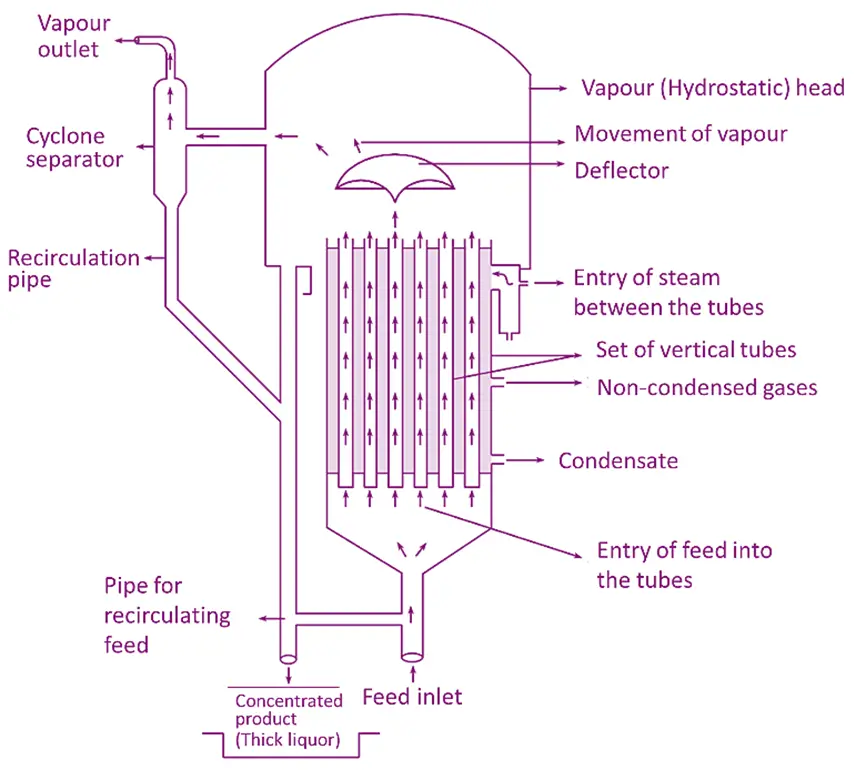

Principle of Climbing Film Evaporator:

- Utilizes the principle of forming a thin film of liquid that climbs up the walls of a heated tube, enhancing evaporation due to increased surface area and reduced film thickness.

Construction of Climbing Film Evaporator:

- Vertical Tubes: Long, vertical tubes where the liquid forms a climbing film.

- Steam Jacket: Surrounds the tubes, providing the heat necessary for evaporation.

- Feed Inlet: Introduces the liquid at the bottom of the tubes.

- Vapor Outlet: For removing the evaporated vapor at the top.

- Concentrate Outlet: For removing the concentrated liquid.

Working:

- The liquid is introduced at the bottom of the vertical tubes.

- As the liquid heats, vapor bubbles form, causing the liquid to rise and form a thin film on the tube walls.

- The film climbs up the tube due to the vapor’s upward force, evaporating along the way.

- Vapor is removed at the top, and the concentrated liquid exits through a separate outlet.

Advertisements

Uses:

- Concentration of heat-sensitive liquids in the food, pharmaceutical, and chemical industries.

- Evaporation of solvents from solutions in the production of extracts and concentrates.

Merits:

- Efficient heat transfers due to the thin film and large surface area.

- Suitable for heat-sensitive materials due to short residence time.

- High evaporation rates.

Demerits:

- Complex design and operation.

- Requires precise control of feed rates and temperatures.

- High initial investment.