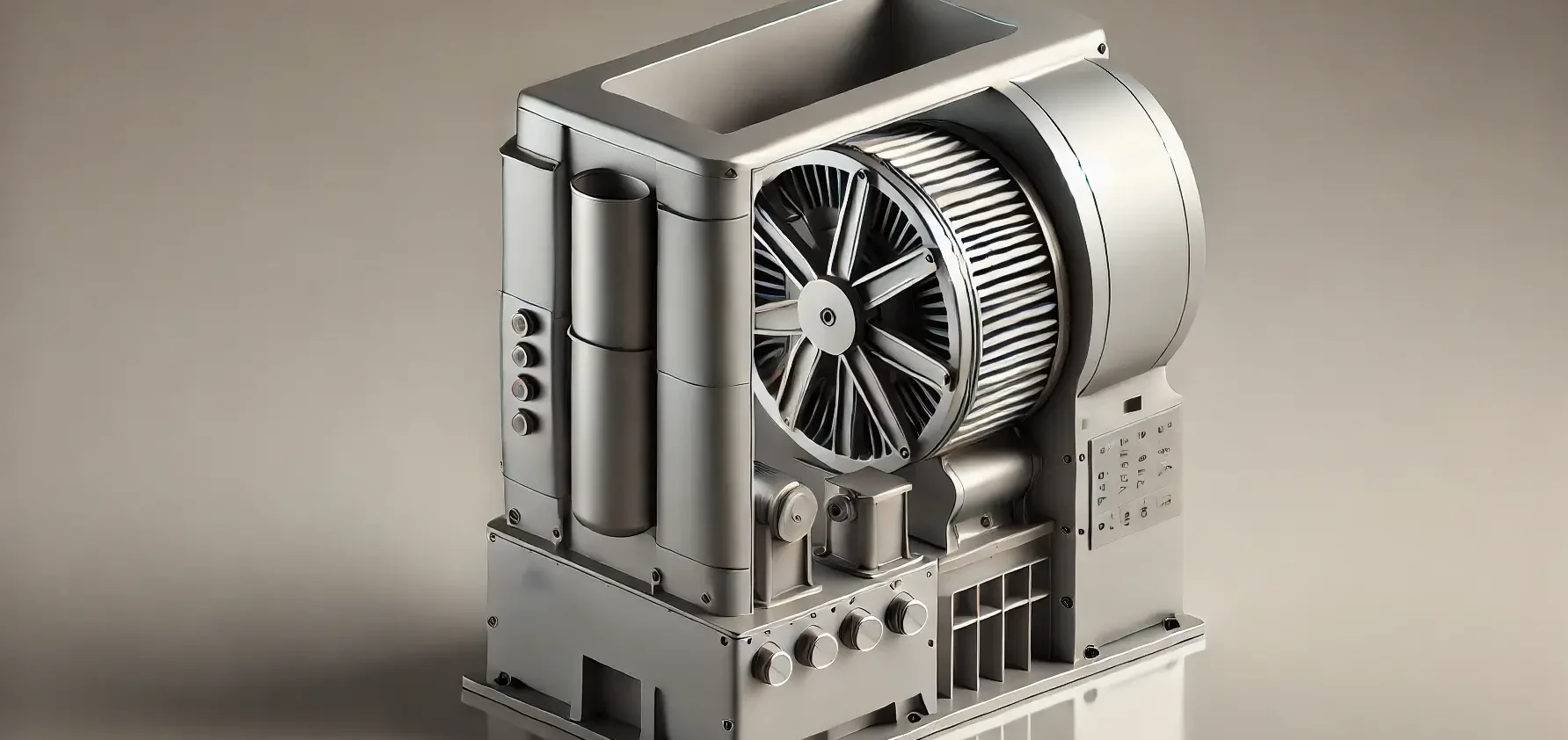

Sieve Shaker

Principles of Sieve Shaker: Operates based on the principle of size separation through sieving. Particles are sorted by passing through a stack of sieves with progressively smaller openings, relying on gravity and mechanical motion to achieve separation. Construction of Sieve Shaker: Sieves: A stack of sieves with different mesh sizes. Shaking Mechanism: A motor-driven device … Read more